Table of Contents

MEET: Manufacturing Energy Evaluation Tool

Fig. 1: Results of MEET in the worksheet BALANCE

Manufacturing Energy Evaluation Tool 2 (MEET 2 beta) is currently being revised. Download available here again after completion. |

Free Download* the outPHit Manufacturing Energy Evaluation Tool (MEET)

*Note: The download link will take you to the Passive House Portal, where you need to login in order to access the tools. Login details to the database may differ from your membership login details to Passipedia. Please sign up to the Passive House Portal in case you don't yet have an account. Registration to the Passive House Portal is free and can be canceled at any time. In case of questions contact info@passivehouse-international.org

The manufacturing energy influences the overall energy balance of a building. The Manufacturing Energy Evaluation Tool (MEET) was developed to evaluate the potential energy expenditures and greenhouse gas emissions (in CO2 equivalents) that arise during the production of building materials and components, and to compare these with the operational energy of a building. This allows for a comprehensive analysis of both energy forms – manufacturing and operational – within a single tool.

MEET thereby is an essential tool for a holistic lifecycle assessment of a building’s energy efficiency. It supports planners and architects in making well-informed decisions that consider both manufacturing and operational energy. It also demonstrates that a marginally higher manufacturing energy for products with superior thermal insulation qualities can be advantageous, as these products frequently result in substantial energy savings during operation. In practice, it is often shown that operational energy has a more decisive impact on the overall energy balance of a building.

For more information on the calculation methods, please refer to this Passipedia page ![]() and the attached report (click on the image to the right).

and the attached report (click on the image to the right).

MEET: Manufacturing Energy Evaluation Tool

The tool is, along with the report, is available for download above. It is a standalone tool that provides a comprehensive evaluation of the manufacturing energy and the greenhouse gas potential of building materials. Simultaneously, it also approximates the operational energy of the building. It assists in the assessment and comparison of:

- Individual materials

- Window components and opaque assemblies

- Entire buildings under specific climatic conditions

MEET 2: Next Generation of the Tool (beta)

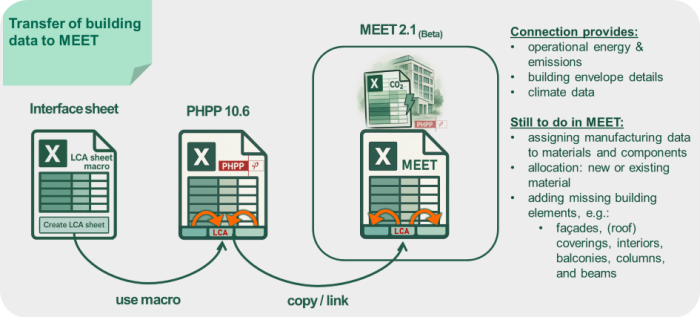

With the introduction of the second version, the tool now offers enhanced functionality and a direct connection to the Passive House Planning Package (PHPP). Specifically, this means:

- User-friendly material selection: The material input has been improved through an extensive building material list and a filtering mechanism. Additionally, the input for windows and doors has been made more intuitive.

- Integration with PHPP: MEET 2 is linked to PHPP 10, enabling a detailed determination of operational energy. All relevant energy data, as well as data on the composition of the building envelope, are transferred easily using an embedded interface sheet.

MEET 2 is currently in its beta phase and undergoing revision. It will be made available here again once the updates are complete. Contact: tools[at]passiv.de

Five-step quickstart: how to use MEET

So how does MEET actually fit into your workflow? Here is a straightforward five-step quickstart:

- Model your project in PHPP (your usual workflow).

Remember to define CO2 factors for your region in the “2-CO2 factors user-defined” sheet. Electricity mixes differ from country to country and are changing constantly. For Germany, for instance, we assumed a decarbonisation pathway over the next 40 years, with average values of 0.198 kg CO2e /kWh for heating electricity (cold period) and 0.093 kg CO2e /kWh for user/household electricity (all year round). Current developments, however, suggest that this assumption may even be somewhat too optimistic. - Request the interface worksheet (PHPP 10.6+) via the contact above. After receiving, transfer envelope + energy data to MEET:

- Use the interface worksheet macro to create the LCA Sheet in your PHPP.

- Include the content of the LCA Sheet in MEET by copying or linking.

- Finally, you can fill out MEET (by doing the things listed under “Still to do in MEET”) and get the results.

- Read the BALANCE sheet: look at both the manufacturing and operational contributions, rank the biggest bars, and iterate the design where it clearly moves the needle.

Keep in mind: the assignment and modification of building envelope components always happens in PHPP.- If you only copied the LCA sheet into MEET and later make changes in PHPP, you need to repeat step 3 to update the data.

- Whenever you change material properties in PHPP, you always need to recheck step 4 to make sure your material data selection in MEET remains correct.

This way, all data in MEET stay consistent and up to date.

Tip: MEET’s strength lies in proportionate attention. If the operational part still dominates the balance, focus first on improving the envelope and systems during operation. Once operation is genuinely low (~PH standard) is it worth investing some time in comparing materials while checking for absolute impact.

Tips for practice

- Compare assemblies systematically: In heating-dominated climates, transmission losses strongly correlate with total demand. Thus, create several possible options of thermal envelope components (walls, roofs, windows…) in PHPP, even if you don’t apply them in your PHPP project. In MEET, you can then evaluate how the manufacturing energy and resulting GWP relate to the theoretical transmission losses per m² of the component. You can find the comparison charts in the input sheets “Opaque assemblies” and “Windos&Doors” to the right.

For cooling-dominated climates, it is better to create PHPP variants and track the resulting outcomes of each variant. - Check building services validity ranges: The values for technical building systems are only valid within certain limits. These “ranges” are shown below the dropdown menus and change depending on the selected device. If your systems are much larger than the given range, you can simply turn off the building services calculation in MEET.

Using your own manufacturing data in MEET

In short, what exactly does MEET need as data input when you hold an EPD (Environmental Product Declaration) in your hands, in order to align with PHI’s method? The tool focuses on three central data points:

- Primary energy of materials: Primary energy resource PERE + PENRE 1) (renewable and non-renewable) of modules A1–A3 (manufacturing). Calorific energy (PERM, PENRM) should not be included.

- Global Warming Potential (GWP): For wood-based materials, MEET accounts for only 40% of the biogenic CO2 credit, in line with current scientific recommendations. This avoids overly optimistic results while still reflecting the advantages of renewable resources. For other fast-growing biogenic materials such as straw, the full credit is retained.

- Service life: Manufacturing energy and GWP are expressed as annualised values, divided by the service life of the material or component.

Our method in a nutshell – scope, boundaries & data

- Comparable results: We intentionally present the results annually (annuitized), enabling direct comparison with operational energy—even if assessment periods differ.

- Embodied indicators considered: In addition to the Global Warming Potential (GWP), we look at the total manufacturing primary energy (renewable + non-renewable). While GWP (as a measure of climate impact) heavily depends on local factors like the energy mix in the production country and can quickly change over time, manufacturing energy provides a more robust measure of production efficiency and is internationally more comparable. This avoids overlooking opportunities for energy savings, as energy that is avoided does not need to be provided at all – whether fossil or renewable.

- System boundary: We focus on the manufacturing stage (A1–A3, as defined in EN 15804: raw material supply, transport, production) and the use stage (B, operation and replacement after completion of construction). These are the phases with the most relevant and reliably quantifiable impacts. Speculative scenarios far in the future (reuse, disposal, recycling) are excluded, as these are highly uncertain, especially considering anticipated advances in circular economy and renewable energies. Caloric energy (= energy stored in material: PENRM, PERM) is also not considered, as it is not decisive for ecological optimization within this context. The service life and thus the replacement need of the materials implicitly enters through the annual presentation of results. We recommend an assessment period of 40 years. While this is much shorter than the expected lifetime of a building, it represents a timeframe that can still be meaningfully assessed according to MEET’s method.

- Adjusted wood biogenic credit: Based on the current state of scientific literature, we apply a reduction of 60% to the CO2 credits usually attributed to wood products, thus counting only 40% of the biogenic credit. This adjustment ensures more realistic results while still considering the positive benefits of the material. For other fast-growing biogenic materials, such as straw, the full credit is retained, since these would otherwise release nearly all of their stored CO2e if not used as construction products.

- Data sources: MEET already includes a comprehensive material database. Values have been initially tailored to the German region (the ÖKOBAUDAT as a main source), but the manufacturing energy figures can also serve as a good-enough approximation for other regions. Compared to GWP, manufacturing energy shows far less variation between countries, making it a more reliable basis for international comparison.

- Adding your own data: Standard databases such as ÖKOBAUDAT and third-party EPDs can be used, with manual recalculation where necessary to align with MEET’s method. See also the section above.

Further reading on this topic

Energy efficiency and greenhouse gas emissions over the life cycle

Life cycle assessments: Methods, criteria and data (availability) for assessment ![]()

Webinar: Introducing MEET - The embodied energy Passive House toolset ![]()

Webinar: Embodied energy and carbon in Passive House construction ![]()

Adequate net zero rating approach chosen for case study projects

Life Cycle energy balances, Embodied energy and the Passive House Standard

See also

Report from Passive House Accelerator MEET: A New Tool for Embodied Energy Calculations

Click Tool to get back to the Passive House tool overview