Table of Contents

Energy efficiency and greenhouse gas emissions over the life cycle

A brief summary of the main results of the AkkP 58 and AkkP 60 Cost Effective Passive Houses Research Group, by Wolfgang Feist

Building life cycle

Buildings play a major role in climate protection and sustainability, as they are responsible for 35% of energy consumption worldwide11) . The carbon dioxide emissions they cause are even increasing by around 1% per year, according to the International Energy Agency2) .

It is therefore crucial whether and, above all, how buildings are constructed or renovated. Discussions are increasingly focusing on “grey energy”3) or the 'CO2 rucksack'4) , while the issue of operating energy - net zero, zero emissions, or plus energy - is being pushed into the background. With the AK58 and AK60 research groups, we have taken up this question again and examined the topic 5) under the current and future boundary conditions and worked out a systematic clarification of numerous questions. We have summarized some important results here: The full contributions can be found in Protocol Volume No. 58: Life cycle

Existing buildings are particularly crucial for achieving the goals of the energy and heat transition. In industrialized countries in the North, these buildings have high heating demands and loads; including air conditioning (mainly in the global South), they account for around 30% of the current total final energy demand and therefore make the highest individual contribution of all. These high demand values can be reduced primarily by retrofitting thermal insulation. The Passive House Institute has provided a whole set of tools for this purpose, the most important of which are the EnerPHit retrofit plan and the ENBIL consulting program (enbil.org). Currently, there is a widespread perception that the upstream energy demand and CO2 emissions of modernization are so important that improved thermal insulation would hardly contribute to climate protection. One of the tasks of these research groups was to quantify this.

Methods

The methodological principles for the life cycle assessment presented here were developed as part of Research Group 58 AKKP 58

Only a comparison of alternative approaches is appropriate for professional decisions: If, for example, there is a variant with a total operating energy expenditure close to zero (i.e. “a zero-energy house”), then the target is fully achieved for this in the operating phase - from the point of view of the relevant ecological benchmarks, the operating phase is then insignificant. However, this in no way allows the assessment that only the production inputs are important - because without the measures, the “zero energy” target would not have been achieved in the first place. Rather, the production inputs must always be assessed in relation to the savings achieved and not in relation to the remaining consumption in the operating phase6) . The simplest method and the most transparent way to do this is to add up the respective total loads over the life cycle for different design variants and thus fully compare the variants.

The key benchmarks for this assessment and comparison are as follows:

1. The Primary Energy renewable (PEr) 7) : This is the (exclusively) renewable energy that must be generated for a specific application (e.g. heating) in a fully renewable supply system: Depending on the energy sources used and taking into account any storage losses and other losses. It is the measure of the effort required in a renewable future8) .

2. The Global Warming Potential (GWP measured in CO2eq), as a measure of climate impact. This is because fossil fuels will continue to be burned, hopefully to a steadily reduced extent, in the transition period until full renewable coverage is achieved.

Life cycle

On the one hand, the life cycle of the building includes the impact from the upstream chains of the materials used: the manufacturers provide the parameters (primary energy and GWP) “from the cradle to the factory gate (corresponding to A1…A3 according to EN 15978)” in the EPDs. These values are generally reliable, but a simple correction (see below) is required for wood products. On the other hand, the primary energy and GWP values of the annual heating and cooling operation, multiplied by the useful life of the building, are dominant, especially for existing buildings. These values are most easily obtained directly from the energy balance9) . The third contribution is the demolition up to removal. In the case of concrete structures in particular, this is perceived to require “a lot” of energy because powerful machines are used. However, compared to the 500 to 700 kWh/m³ of primary energy required for production, this is objectively a small contribution. Even if components with a useful life of only 40 years, for example, are involved, this ultimately only results in a contribution of less than 0.25 kWh/(m²a), even for solid construction. Subsequent use can and must be accounted for separately after use for the then known specific purpose. Under discussion here are processes that normally take place in 40 years at the earliest (usually much later). It is impossible for us to determine or even define today what will happen to an affected structure at such times10) .

New building

Given the current level of new construction activity in Germany, it is by no means the case that additional new construction of whatsoever will improve climate protection.11) As a rule, however, new construction increases overall emissions even today; only occasionally can a newly constructed building reduce emissions and then only to a small extent. Even then, it is generally cheaper to modernize an existing building in a minimally invasive way to a good energy efficiency level.12) The climate gas emission reductions achieved are usually significantly higher. In AkkP 60, we have shown that a net-zero or slightly negative-emission building can be realized today with a reasonable amount of effort, but still cannot significantly compensate for other emissions. Careful planning, both in terms of production energy and operating energy demands, does therefore not mean that every new building is 'forbidden'13) .

Heating systems

Sustainable systems for space heating are exclusively heat pumps and sustainable district heating14) . For heat pump electricity, emissions result in 198 gCO2 /kWhel on average over the next 40 years15) which makes the heat pump about two to three times better than natural gas heating 16) . In addition, the heat pump offers the well-secured potential for an almost complete reduction of greenhouse gases in the further future due to the necessary expansion of non-fossil electricity supply.

Insulation measures: If you do it, do it right

For the thermal insulation measures implemented, it was confirmed that the guiding principle of “if you do it, do it right” also remains fully valid within the full life cycle assessment. The additional effort for the respective thermally improved measure (low thermal bridges, airtight and a U-value of 0.15 to 0.2 W/(m²K)) compared to less effective measures during implementation is low. This applies not only to the material expenditure, but also to the associated energy input and the resulting emissions. With this guiding principle, it is possible to halve the usually achieved reduced consumption values once more, regularly without generating significantly more production effort - neither in terms of costs nor in terms of energy inputs or climate-relevant emissions.

Wood products

Currently (2024), the entire CO2 equivalent of the carbon content of renewable raw materials is usually calculated as a CO2 credit (quasi a permanent “sequestration of carbon in the building”); however, such an assumption of the full carbon dioxide equivalent for materials is only correct if the material

- either occurs anyway as a by-product of ongoing economic processes and is otherwise generally incinerated if it is not recycled (e.g. cellulose insulation made from waste paper or OSSB panels made from rice straw in China), or

- is used as an alternative to a complete greenhouse gas release process (e.g. grass-fiber thermal insulation obtained from grassland).

We therefore propose continuing to apply the full calorific CO2 sequestration for components made from straw, grass and waste paper per mass of material used17) .

However, the situation is different for products made from wood: Since in the currently practiced form of forest management trees are felled in a phase with still high photosynthetic activity, the build-up of carbon storage in the forest is reduced as a result of the removal. According to the opinion of the majority of expert authors, this is not to the full extent of the carbon content in the product, but the net increase in sequestration must nevertheless be corrected by the amount of the reduced photosynthetic capacity. From existing publications on forest productivity in developed countries, with different forest types and (predominantly temperate) climates, we were able to calculate the applicable sequestration performance for products made from wood at an average of

0.74 kg CO2 per kg of wood in the product

in the product. The values determined from the studies show a spread of around 34% 18) This means that in the vast majority of cases, the values can lie between 0.48 and 1 kg CO2 per kg of wood. These values can be recognized as sequestration if the products (or their carbon content) are permanently stored and not burned after use.

Building stock

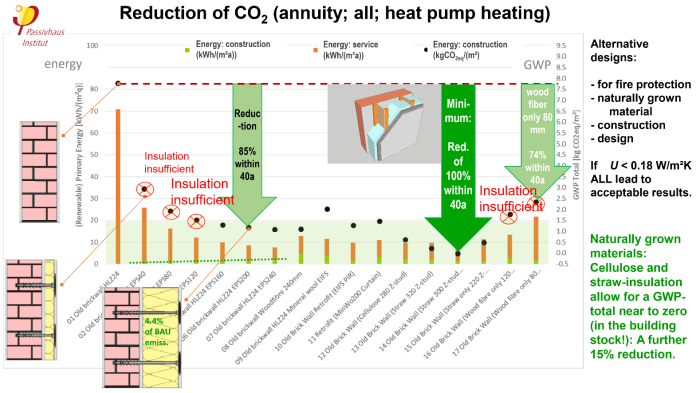

The figure shows results from Research Group 58 for the total renewable primary energy PEr (left axis) and the total GWP (right axis) of a typical external wall in an existing building. For this purpose, the service life of each individual layer was taken into account and integrated over the entire life cycle, then divided by the period under consideration to obtain average annual emission values for better comparability.

The decisive conclusions are

- The uninsulated construction (even with the use of a heat pump) is far outside the sustainability field with emission values that are more than a factor of 4 above the budget available for sustainable buildings (see AkkP 58, shown here as a light green band).

- All the insulation measures listed improve the situation considerably, but not all of them also lead to the sustainability field.

- All sufficiently well executed insulation measures (i.e. free of thermal bridges and sufficiently thick) meet the sustainability criterion and reduce the equivalent CO2 emissions in the life cycle by more than 80%; with the sole exception of ETICS with mineral fiber boards of high bulk density (structure no. 9), this structure is needed due to fire protection, but still offers a reduction of around 74%. All external thermal insulation composite systems with an insulation thickness of more than 120 mm also fall into the sustainability category (with the exception of mineral wool, which is essential for fire protection in high-rise buildings). This is illustrated using the example of ETICS with grey EPS insulation boards, columns 2 to 8. The recommended insulation thickness here is 200 mm (green arrow), with a net saving of 85% of emissions in the life cycle (including production), which is another 7 percentage points more than with the often 'usual' 10 cm.

- The expenditures resulting from the production upstream chain (shown in green in the diagram for PEr, at the bottom) are only just noticeable in the diagram with high insulation thicknesses, e.g. with the recommended insulation thickness of 200 mm they amount to 0.39 kg/(m²a) or 5% of the original life cycle emissions of the non-insulated wall. The payback period for the GWP here is around 2 years for heat pump heating 19)

- The emissions avoided during operation of the building prove to be by far the dominant factor for all variants. For every type of construction, “if you do it, do it right” applies to the choice of insulation thickness.

- Curtain walls with blown-in insulation materials made from renewable raw materials perform even better. Here too, of course, care must be taken to ensure sufficient insulation thickness: The U-values must be kept below 0.25 W/(m²K) in order to reach the sustainability range. Target U-values below 0.18 W/(m²K) are also recommended here; in some cases, using these solutions zero emissions in the life cycle balance can be achieved.

The conclusions for windows (glazing and frames), ventilation heat recovery and other building technology are discussed in the following Research Group project [AkkP 60]. It turns out in all cases that the recommendations according to EnerPHit always lead to results that fall below the sustainability limit and thus offer a durable solution. The decisive factor for implementation is that there are cost-effective design variants for the EnerPHit solutions. Planning these and implementing them into practice is therefore the main task for achieving sustainable solutions for existing buildings 20) .

Really saved energy? Even in the first year?

Thermal insulation materials require energy for production (so-called “grey energy”). Even in the case of conventional insulation materials, however, this is very little compared to the savings achieved by the insulation measure. In the first of the following diagrams, we compare the primary energy consumption of one square meter of uninsulated old building wall in just one year with the sum of the total production primary energy expenditure 21) and the remaining “residual consumption” for a retrofitted insulated wall in eight variants. All of them (with the exception of the wood insulation) already save a considerable amount of energy in the first year, and recover their respective production energy expenditure in the first heating period 22)

Of course, this must be considered over the entire service life. Even if we assume less than 20 years, savings of over 80% can be achieved in the overall balance with sufficiently thick external insulation (second diagram). Perhaps someone would like to do the math themselves? This is not difficult at all, here are the instructions.

Sources

[AkkP 58] Research Group on Cost-Effective Passive Houses: Energy and CO2 emissions in the life cycle | Part 1 / Arbeitskreis kostengünstige Passivhäuser: Energieeffizienz & CO2-Emissionen im Lebenszyklus | Teil 1, Darmstadt 2024, available for free download see Volume No. 58: Life cycle assessment

[AkkP 60] Research Group on Cost-Effective Passive Houses: Energy and CO2 emissions in the life cycle | Part 2 / Arbeitskreis kostengünstige Passivhäuser: Energieeffizienz & CO2-Emissionen im Lebenszyklus | Teil 2, Darmstadt 2024, available for free download see Volume No. 60: Life cycle assessment

See also

Webinar: Introducing MEET: The embodied energy Passive House toolset

Life cycle assessments: Methods, criteria and data (availability) for assessment

Life Cycle energy balances, Embodied energy and the Passive House Standard