Table of Contents

Compact HVAC systems

General idea - Heating and cooling via the hygienically required fresh air supply

Every house that is occupied by humans requires fresh air.

- If the fresh air supply is left to chance, it shouldn’t be a surprise if there is poor indoor air quality.

- If heat is not recovered from the used air, there will be high ventilation heat losses – this isn't the way to achieve an energy efficient building with a good quality of indoor air.

Home ventilation with passive heat recovery is indispensable in new constructions and in energy efficient refurbishments! See also the article about home ventilation, as well as the article comparing the efficiency of passive versus active ventilation heat recovery.

The supply air coming from the heat recovery device can also transport a small quantity of heat. Just 10 W/m² of fresh air that is indispensable for hygiene can be provided for the supply air rooms (see heat capacity of fresh air). In a Passive House, the heating power requirement is extremely small - so small that it can be met by the 10 W/m² provided by a supply air heating system. Similarly this concept also applies for the low cooling loads of a Passive House building.

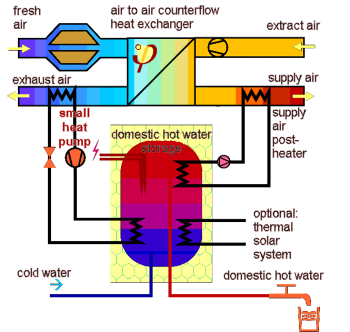

This makes it possible to develop convincingly simple building services systems for Passive Houses: “heating via ventilation systems”, without the need for additional ducts or larger ducts. If supply air heating and hot water provision is integrated into the same ventilation unit, we have a compact ventilation unit: heating, ventilation and hot water generation in one. Such systems can also include active cooling and dehumidififcation for use in warmer climates. Various solutions are possible for generating heat. Each of which are described in more detail below.

- Concept 1: Using a small exhaust air heat pump (compact heat pump unit)

- Concept 1a: Using a small heat pump in the exhaust air that can also provide cooling and dehumidification

- Concept 2: Using a small condensing boiler

- Concept 3: Using a small heat generator based on biomass fuel

Concept 1 - Heating using the residual heat from the exhaust air: The compact heat pump unit

The amount of residual heat in the exhaust air of a home ventilation unit, also known as “enthalpy”, isn't particularly high, and condensing moisture contained in the air accounts for a large part of it. However, in a Passive House, the heat requirement is so small, that it can be covered almost completely by this residual exhaust air enthalpy. This concept was first published in 1995 by Wolfgang Feist, which facilitated the development of such systems. See this article for more details about the energy balance and certification criteria of compact heat pump units ![]() for Passive House buidlings.

for Passive House buidlings.

Today, an increasing number of manufacturers offer such compact ventilation units. These units are highly efficient, as proven by scientifically evaluated measurements in Passive House housing developments.

Concept 1a - The extended compact heat pump unit: Exhaust air heat pump for heating, cooling and dehumidification (& DHW)

As soon as some active cooling in summer is necessary 'extended compact heat pump systems' are the best choice that allow heating, as well as cooling and dehumidification with one integrated system using a reversible heat pump for heating in winter and cooling + dehumidifcation in summer. Such a combination of ventilation with passive heat recovery (HR) and an exhaust air heat pump (HP) for heating and cooling and dehumidification is a highly attractive integrated system that is easy to install and easy to operate in single family homes and in individual apartments in multi family buildings. In recent years, such units have become increasingly popular in Chinese multi family Passuce House buildings, as there in most regions cold winter and quite long hot summer periods require heating and cooling to be combined.

The additional service of delivering DHW by the same heat pump would be very welcome as - especially in summer - DHW can be fully provided by the waste heat from the cooling operation. These extended combi-systems just need an appropriate water tank and a more sophisticted controller and all parts to be well combined. The basic technology components are already available but only few of these fully integrated systems are currently available on the market (mainly for cost reasons). See also this article for recommended mechanical systems in tropical climates.

Concept 2 - Heating using biomass: The compact pellet stove unit

Of course, not only Passive Houses can be heated using biomass. However, the available potential of sustainably-produced fuel is limited. In case of poor efficiency, only a fraction of the buildings in Europe (and also worldwide) can be sustainably supplied with biomass. However, if the level of efficiency is high enough, as it is in the Passive House for example, then the amount of fuel provided by sustainable agriculture and forestry is sufficient to cover a considerable share of the energy demand.

A high level of efficiency also benefits the user. If the required heating power is only between one and two kilowatt, it can be covered by the biomass heating device, a small box which doesn't require much space but can heat the whole house. This has a number of advantages:

The biomass heating device runs completely automatically, just like modern heating systems. Only a few kilogrammes of pellets for fuel are required per day. Not much space is needed to store this – it would even be possible to get the small amount of fuel along with the weekly shopping. The necessary combustion air can be drawn in with the fresh air by the compact unit. The very small volume flow rates of exhaust air can be extracted by the heat recovery system of the compact unit together with the exhaust air; there is no need for a separate chimney or flue pipe. Hence, the result is a simple building services concept for the Passive House based completely on renewable energy sources, that is still being developed and unfortunately is not yet available on the market.

There are already some Passive Houses in which heat is mainly generated by using a standard wood-pellet stove (Passive Houses Friedberg).

Concept 3 - Heating using a condensing boiler: The gas-based compact unit

Every user of gas stoves knows that even with a low output, heat generation is possible with gas. In spite of that, it took a long time before this technology could be used for post-heating in Passive House compact units. The advantages are obvious:

- The condensing boiler requires very little combustion air. The ventilation system, which is the central component of each compact unit, can easily provide this amount of combustion air along with the fresh air, therefore separate combustion air conduction is not required.

- Condensate accumulates in the condensing boiler which must be drained away via a condensate pipe. Ventilation units with a cross-flow heat exchanger must also have a condensate drain. In the compact unit, these two parts are combined cost-effectively.

- The exhaust air duct of the ventilation unit is already present for transporting exhaust fumes from the condensing boiler, thus dispensing with a separate exhaust pipe; however, this is possible only if the output is very small and if the quantities of exhaust fumes produced are small.

Other concepts

Compact ventilation units are not the only building services solution for Passive Houses: The low heating and cooling loads allow a wide variety of effient heating and cooling systems. Efficiency and renewable energy complement one another ideally: with the low consumption of the Passive House, meeting most of the requirement through solar energy becomes possible.