Table of Contents

Building automation

Original German article: PB 59 – Energieeffiziente Nichtwohngebäude – die Potentiale der Gebäudeautomation optimal nutzen Author: Wolfgang Hasper

The achievable level of energy efficiency of buildings is mainly determined by the building design and selection of the quality of building components during the planning and execution phases. Consumption later on is also influenced by actual building use. In non-residential buildings, control parameters have an influence to a relevant degree (e.g. operating times, supply temperatures, air volumes/balancing of ventilation systems). Building automation offers an opportunity to optimise operation in terms of energy. However, appropriate control variables and strategies for typical non-residential Passive House buildings may differ from conventional approaches. Identifying malfunctions as well as unsuitable operating parameters based on consumption control is the task of technical monitoring, which is recommended for systematic commissioning and optimising operations. Last but not least, the perspective of the users should always be considered right from the planning stage, which explicitly includes the technical operations personnel.

Introduction

For the operation of ordinary non-residential buildings, the automation of important functions is a necessity without which economic operation cannot be achieved. Energy efficient, optimised operation of the building can also be ensured if this is properly designed and executed. It also includes the possibility of data collection on a wide scale for systematic operations monitoring.

Away from these ideal concepts, actual project experiences are often disillusioning. The functions in building automation are not always satisfactory and, especially in Passive House buildings, often aren't adapted to the requirements of energy-efficient operation. For example, there is almost a conflict with traditional approaches in the area of ventilation systems with heat recovery. The commonly used bypass control targeting a specified supply air temperature of e.g. 20 °C, regardless of the other boundary conditions in the building and time of year leads to unnecessary ventilation losses on mild winter days and wastes a cooling potential in the summer. Balanced operation and adherence to planned operating times are central to overall efficiency, but are not always successfully realised. Unintentional summer heating and increased system losses due to poorly adjusted flow temperatures have also been identified in many monitored projects.

A frequent point of disagreement with users as well as with the requirements for efficient operation is the control of shading systems when they are operated without regard to the season and individual preferences.

In many cases, a quantitative evaluation of operating data is hampered by the barely known and usually considerably too large measurement uncertainty of the sensors used. In some cases, even the control system cannot work accurately, especially in low-temperature systems with concrete core temperature control, where even small temperature differences of a few tenths of a Kelvin are significant. However, the lack of clarity does not just end with measurement uncertainties. With many building automation systems, it is very difficult to gain an overview of the implemented algorithms and parameters of the individual controllers and document the current status in each case if adjustments are made. Also, changes are often difficult to implement and can only be carried out by a very limited group of people, which usually involves a high degree of organisational effort and high costs even for simple adjustments. For commissioning and the interlinked performance optimisation, this constitutes a severe impediment; operation according to plan becomes achievable only after years of committed work. Protectionist trade practices often exist on the part of suppliers and the client is trapped in a proprietary system with unsatisfactory performance and high costs.

Lastly, quite often an appallingly high auxiliary power consumption is ascertained for building automation/controls technology - sometimes greater than the heating demand of a typical Passive House building! In addition to the costs, there is also impairment of thermal comfort in summer for occupants and a high potential for improvement in ecological terms. In order to arrive at good automation solutions for Passive House buildings, it is important to bring their special features to the attention of the suppliers concerned. This is because with regard to their behaviour, these particularly energy-efficient buildings differ from buildings of the past. A good building envelope greatly reduces heat loss towards the surroundings, so the building's heating demand depends less on the outside temperature and more on free heat from solar gain and usage (presence of people, use of electrical appliances, lighting).

Conventional control systems are often based on an outdoor temperature-dependent approach for e.g. the forward flow temperature for heating. In a Passive House building, but also in less efficient buildings, this cannot lead to really good results; at the very least, there will be an unnecessarily high system loss for the provision of heating energy that cannot be used to the relevant degree. In conjunction with heat pumps which are becoming increasingly important and whose efficiency depends on the temperature level to be provided to a far greater extent than in other systems, suitable control algorithms become even more important.

The interactions between buildings and the energy system, the short and long-term storage processes as well as the characteristics of generators can be well represented with the Primary Energy Renewables (PER) system and operationalised in daily planning practice. This provides a reliable guideline for decisions in the planning process.

Within the building, well-planned and adjusted automation ensures optimal operation of the technical building systems, preferably with a low power requirement for their own functioning. Systems are precisely controlled, and forward flow temperatures are limited to the necessary level. Automation systems that record the respective building condition with sufficient accuracy can contribute to grid-appropriate operation of heating systems and other installations. If clever use is made of the thermal capacity in a Passive House building, the heating system can be switched off completely for longer time periods or even days and the load can be shifted accordingly. In an existing building, this is only possible for half a day at the most. This flexibility can be an advantage for a renewable energy system. However, one must keep in mind that the potential for such time shifts is quantitatively limited - the thermal capacity of a solid construction that can be used for load shifting is in the order of one kilowatt hour per square metre of floor space in practice.

Legislators at the European Union level have recognised the opportunities offered by building automation, although the hoped-for effects are probably overestimated. The European Buildings Directive [EPBD 2018] emphasises the opportunities for optimisation during building operations. It sees a growing importance of Building Automation and Control Systems (BACS) and specifies that where possible, all non-residential buildings with systems with a rated output of over 290 kW must be equipped with automation functions by 2025. However, this already includes simple thermostatic control of radiators, which is self-evident in all regions of the EU. Nevertheless, the member states must also ensure that functions for analysing energy consumption are installed in such buildings. There is also a requirement for manufacturer-independent communication between different systems in the building. For buildings with nominal capacities between 70 and 290 kW, building automation is additionally made attractive by dispensing with otherwise mandatory physical inspections of heating and air conditioning systems.

For Passive House buildings, these regulations only apply in the rarest of cases, because with a heating load of 10 W/m², they would only be applicable from a treated floor area of 30,000 m² onwards. However, the trend towards building automation continues, and in the latest draft of the EPBD of December 2021, the limit for this requirement will be lowered to 70 kW. From 2025 [EPBD 2021] onwards, automation of energy-relevant control and monitoring is envisaged even for new residential buildings and such buildings that have undergone deep retrofits.

Assuming non-modernised existing buildings, it is understandable that a favourable cost-benefit ratio is expected for BACS. With thermostatic valves in all rooms, night-time setback and flow temperature control, savings can quickly be achieved here. The absolute amount will also justify the cost of the measures, so implementing such “first aid” measures is certainly recommended. However, with regard to the desired transformation of the energy system, this relatively small improvement can never replace a deep energy retrofit of buildings, without which the winter heating energy demand cannot be limited to an acceptable level. In the following sections it will become clear that even then, the savings that can be achieved through building automation are still interesting, but will be lower.

Potentials of building automation

A Passive House primarily features an optimised building envelope. Heat losses are minimised, high solar heat gains are desirable in winter. Free heat, i.e. passive solar heat and use-related heat therefore naturally contribute significantly to make up for heat losses in winter. Effective shading avoids overheating of the rooms in summer, but provides adequate daylight. The lean but optimised building services systems consist mainly of a ventilation system with heat recovery dimensioned for the necessary hygienic air exchange. Their operating times are based on the times of use, with regular shutdown outside of this time. Compared to conventional buildings, the heating and cooling technology is of lesser importance, as the required outputs are low and the amounts of energy converted are manageable.

In any case, the building represents one system in which all parts interact. Dividing the building automation system according to the different trade disciplines is (still) common during construction, but in the operating phase it does not make sense and regularly leads to difficulties that are challenging to resolve later on.

The frequently encountered parallel structure of partial automation systems of the various trade disciplines usually does not produce satisfactory results because the exchange of information between the subsystems is incomplete or even non-existent. For example, a shading system cannot react to the room temperatures or heating operation, or a ventilation system cannot reduce heat recovery at the right time in spring.

In addition, commissioning is also made more difficult since several usually quite different systems have to be understood, operated and optimised. The availability of data for operations monitoring is accordingly just as limited and scattered across several sources. Simply the collation of data alone is a challenge.

It is therefore expedient to set up a single, cross-discipline automation system. The thermal condition (more of which later) of the building can provide a useful parameter for the coordinated control and regulation of building functions.

Studies with dynamic thermal building simulation clearly show that the energy-saving potential of building automation is significantly influenced by the efficiency standard of the building. Even with perfectly optimised functioning of all automation systems, parameter variation shows only a very low energy saving potential through optimised controls in Passive House buildings. Assuming a general savings potential through building automation is not justified here.

A significant effect can only be achieved in old buildings or poorly insulated buildings, especially by exactly maintaining the desired room temperature and using the setback mode outside of the time of use.

The major savings potentials clearly lie in the quality of the building fabric, and the Passive House standard can achieve enormous improvements both compared to the existing building stock and to the statutory minimum requirements. Retrofitting a building automation system therefore cannot be a substitute for an energy retrofit of the building envelope, even in existing buildings; at best, it represents a swift, effective first step of the measures.

In non-residential Passive House buildings, there is a favourable response with very little influence on energy consumption due to deviations. Extending the daily usage times has hardly any noticeable influence on the energy consumption. Nevertheless, setback periods outside of the times of use with back-up operation/standby mode at 17-18°C is effective to a smaller extent and can be useful given the typically long downtimes of non-residential buildings. The accordingly slightly higher heating load must then be taken into account; guidance on this is given in AkkP 51.

Seasonally different control schemes of shading equipment is necessary in order to allow solar heat gain in the winter and to avoid overheating of rooms in the summer. A threshold value of approx. 150 W/m² (global radiation) on the façade plane is a reasonable guideline.

Demand-based control of lighting installations can save significant amounts of electrical energy if these have a low auxiliary energy demand, including that for standby mode. This can support, but cannot be a substitute for, attentive building planning for a high degree of daylight autonomy and optimised specialist lighting planning.

The extent of appropriate building automation systems for non-residential Passive House buildings will usually achieve a rating of A or B on the rating scale in EN15232-1:2017, which ranges from A to D. However, it cannot be concluded from this that an automation solution with an A rating will already be suitable for Passive House buildings. Rather, automation concepts that are meaningfully adapted to the special features of such buildings are decisive, see also the article Concepts for automation in non-residential Passive House buildings.

Concepts for automation in non-residential Passive House buildings

In order to find suitable concepts for building automation, it is helpful to keep in mind the basic motivation to construct buildings. Buildings make it possible for human activity to take place irrespective of the weather and seasons. In a way, they represent the “third skin” of the users after clothing. People with office jobs spend 90 % of their lifetime inside buildings.

In order to meet the complex requirements associated with this, a key objective is to ensure comfortable indoor conditions. Thermal comfort contributes significantly to this, and indoor air quality is equally important. Visual conditions must also be conducive to the given visual tasks and general well-being.

In view of the urgently needed sustainability transition, all these requirements should be met with a low energy input, so that the buildings can be easily and cost-effectively operated using renewable energy sources. Free heat covers a major part of the heat losses in a Passive House building in cool-temperate climate, typically around 60 %. In order to ensure the designed performance these heat gains must be secured by appropriate control concepts. This calls for room temperatures to be allowed to fluctuate within a comfortable band (typically 20…23.5 °C) during the cold season without immediate reduction of the heat recovery or even cooling. While the heating system warrants a lower limit for the room temperatures they must be allowed to rise due to solar or internal heat gains in order to transfer heat to the thermal mass of the building for later use.

To be able to precisely control and regulate technical building systems, it is necessary to know the seasonal operating mode:

- If it is winter, the heating system in the building should be activated, the ventilation system should be operated with heat recovery and the shading elements should remain deactivated in general in order to utilise passive solar heat gains.

- In early spring, the heating system should be switched off at first, but heat recovery of the ventilation system should remain active, and solar heat gains will still be needed.

- Later on, heat recovery should be disabled and shading should be operated to limit solar gains.

- In summer, night-time ventilation or another method of heat removal should be activated if necessary.

A similar process should be followed in reversed order at the approach of autumn and winter.

In efficient buildings, the customarily used outdoor temperature is no longer a suitable basis for controlling the heating or estimating processes inside the building.

A dynamic model-based approach which takes into account all influences of the weather (especially outdoor temperature and solar radiation) in addition to the usage-related heat gains etc. is very complex and too rigid for changes in use.

However, the building itself continuously integrates all influences in the temperature of the deep building mass (concrete core temperature). This represents a suitable (low-pass) filter for the more strongly fluctuating room temperatures, and provides clear indications of the long-term development.

This kind of control concept, based on directly measured concrete core temperatures, was successfully implemented in the FOS/BOS Erding school project and extensive monitoring was carried out with funding by the DBU (German Environment Foundation, Project Number 26170/02). The control concept proved to be very successful; the concrete core temperatures from a larger number of rooms were averaged and the thermal condition of the building was determined from the average temperature. By defining thresholds and hystereses, it was possible to switch automatically between heating, neutral and cooling mode:

| Mode | 24 h average concrete core temperature ϑThZ [°C] (hysteresis) |

|---|---|

| Heating: enabled heating, HR on | ≤ 22,0 (22,2) |

| Neutral | ≥ 22,2 (22,8) |

| Shading, HR bypass | ≥ 23,0 (22,8) |

| Cooling: night-time ventilation | ≥ 23,5 (23,4) |

Any unwanted short-term alterations in the operating status were reliably avoided due to the inertia of the building's thermal mass. Conversely, it was possible to respond automatically to unusual weather or usage phenomena such as late cold spells or increased internal heat gains without problem.

Determining the thermal condition from measured room temperatures

Determination of the thermal condition from direct measurement of the concrete core temperature has proved to work well, but this measurement is relatively costly as it requires an additional number of sensors which must be set up, maintained, calibrated and evaluated. However, the thermal condition for a room can also be calculated with sufficient accuracy on the basis of the prevailing room temperature using a simple thermal model of a concrete ceiling.

In this way, the desired information can be provided easily and cost-effectively, based on data from room sensors that are specified for general control purposes anyway. Data from a number of suitable model rooms are averaged and smoothed over a period of 24 hours in order to obtain the thermal condition of the building. The systems can be controlled according to this figure. Going beyond the approach used for the FOS/BOS Erding, more refined threshold values are defined which could look like this for example:

| Mode | 24 h average building component temperature ϑThZ [°C] (hysteresis) |

|---|---|

| Heating | ≤ 20.4 (20.6) heating enabled, HR active, shading open |

| Neutral cool | ≥ 20.6 shading open, HR active |

| Neutral warm | ≥ 22.5 (22.3) shading closed if ≥ 150 W/m², HR deactivated if Tout < 28°C |

| Passive cooling | ≥ 23.5 (23.3) night-time ventilation active |

| Active cooling | ≥ 24.5 (24.4) cooling enabled |

The solar radiation value of 150 W/m² (~15 kLux) should be understood as global radiation incidence on the affected facade plane (as an easily editable entry).

The switching values given here are exemplary and prove to work well in the simulation model. For a real automation system these must be easily editable so that they can be optimised for a specific building.

Further differentiation is conceivable for example by regulating the heat recovery of the ventilation system according to the thermal condition throughout the building, the heating system according to the minimum that occurs under the thermal conditions of the individual rooms, and the cooling system according to their maximum. Whether this additional complication does actually promise any improvement must be assessed in each individual case. A building-wide approach should be sufficient in many cases. A hysteresis of 0.1 to 0.2 K seems reasonable, and also corresponds to the experiences gained with the FOS/BOS Erding project.

Calculation model for core temperature of building components

The following code snippet (Python) gives an impression of the model. It requires minimal processing power and can be used on any microcontroller, even battery-operated decentral devices can easily derive this information. This example assumes a 10-minute measuring interval for the room temperature, but can be easily adapted for other data rates.

# Passive House Institute GmbH, Research Group for Cost-effective Passive Houses 59,

# 'Energy efficient non-residential buildings – optimal utilisation of building automation potentials'

# Wolfgang Hasper, 2023

# This program is free software: you can redistribute it and/or modify it under the terms of

# the GNU General Public License as published by the Free Software Foundation, either

# version 3 of the License, or (at your option) any later version.

# This program is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY;

# without even the implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE.

# See the GNU General Public License for more details.

# You should have received a copy of the GNU General Public License along with this program.

# If not, see <https://www.gnu.org/licenses/>.

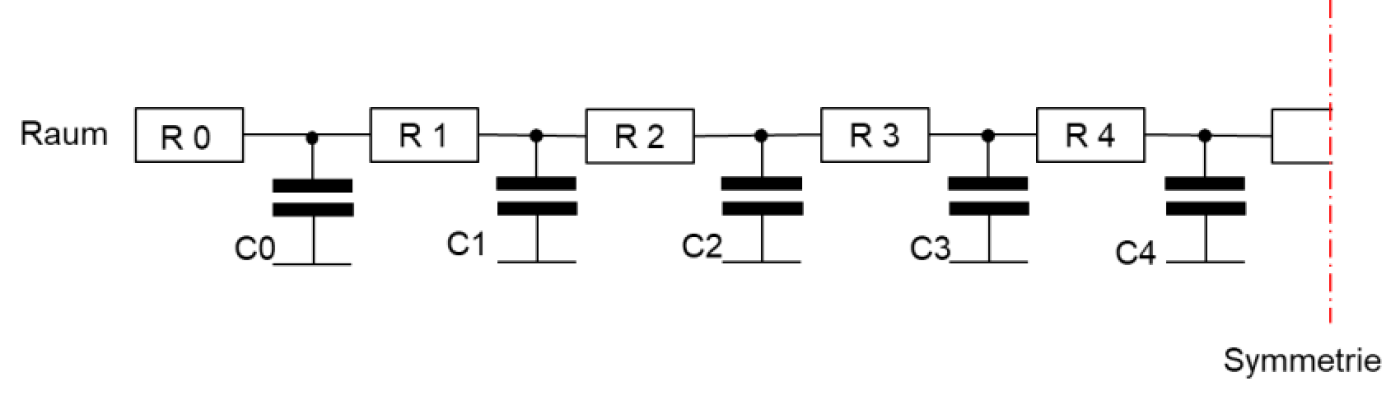

# A dynamic resistor-capacitor (RC-) model of a massive concrete member

# to approximate the concrete core temperature from measured

# room temperatures as are usually available in building automation systems

# in order to save the spending (expenditure) on dedicated concrete core temperature sensors.

# The synthetic concrete core temperature presents a useful form of low pass filter, the

# result indicates the thermal condition of the

# building and can hence be used to control systems accordingly.

#

# Assumptions:

# Over long periods of time equalised radiative temperature within the

# entire room can be assumed for well-insulated buildings ("thermal short-circuit"):

# The radiative heat exchange between room-defining surfaces (~5.8 W/K) dominates any

# other heat transferring processes.

# Hence the assumption room temperature = surface temperature of the concrete member is a justified

# approximation.

# This eliminates all complications of the variable convective heat transfer coefficient.

# The model is further symmetric.

#

# The model considers 5 layers of reinforced concrete

# and 1 unit area (1m²)

# The innermost node is the symmetry point (index 5)

#

# density rho kg/m³

# spec capacity c Ws/(kgK)

# conductivity LAMBDA W/(mK)

# heat flux Q W

# conductance L W/(m²K)

# capacity C Ws/(Km²)

# total nodes N -

# node n -

# time step DT sec

# layer thickness m

# Room temp. tr °C

# start conditions:

# temperature within neutral band to ensure a reasonable start

# in summer or winter

# room temperature tr is fed into the function in regular intervals

def RCmodel(tr):

# constants

RHO = 2400

C = 1080

LAMBDA = 2.1

D1 = 0.025

D2 = 0.025

D3 = 0.025

D4 = 0.025

D5 = 0.025

# surface heat transfer coefficient, approx. 5.8 W/(m²K) radiative, convective disregarded as highly depending on direction of heat flow

L0 = 5.8

L1 = LAMBDA / D1 # W/(m K) * 1/m = W/(K m²)

L2 = LAMBDA / D2

L3 = LAMBDA / D3

L4 = LAMBDA / D4

# symmetry / adiabatic boundary

# L5 = 0

# area specific capacity of each layer

C1 = D1 * RHO * C # m * kg/m³ * Wsec/(kgK) = Wsec/(m²K)

C2 = D2 * RHO * C

C3 = D3 * RHO * C

C4 = D4 * RHO * C

C5 = D5 * RHO * C

# time step in seconds

DT = 60 # Internally the model operates on a 60 sec timestep, for reasons of numerical stability

# Model geometry:

# q1 q2 q3 q4 q5 q6 = 0 = symmetry

# Room temperature tr -L0 - C1 - L1 - C2 - L2 - C3 - L3 - C4 - L4 - C5 - L5

# t1 t2 t3 t4 t5

#

# The temperature t5 of C5 is the desired result

global t1

global t2

global t3

global t4

global t5

# loop the model for the number of 60-sec time steps that fit the room temperature data interval

# e.g. for a 10 minute room temperature data interval this will be 10 loop cycles (0...9)

for x in range (9):

#n = 1

q1 = L0 * (tr-t1) + L1 * (t2-t1) # W/(K m²) * K = W/m²

q2 = L1 * (t1-t2) + L2 * (t3-t2)

q3 = L2 * (t2-t3) + L3 * (t4-t3)

q4 = L3 * (t3-t4) + L4 * (t5-t4)

q5 = L4 * (t4-t5)

t1 = t1 + (q1/C1 * DT) # W/m² * m² K/(W sec) * s = K

t2 = t2 + (q2/C2 * DT)

t3 = t3 + (q3/C3 * DT)

t4 = t4 + (q4/C4 * DT)

t5 = t5 + (q5/C5 * DT)

return t5

# for control applications best use a 24 hour running mean of t5 / the thermal condition, in order to

# smooth out the slight diurnal cyle

Control of system temperature of heating

The temperature level in heating systems should be adapted to the demand in order to avoid unnecessarily high heat losses in heat generators and distribution systems, to allow condensation of water vapour from combustion processes, and to increase the coefficient of performance of heat pump systems.

In intermittently operated non-residential buildings, the heating system is switched to back-up mode at night and on weekends for maintaining a minimum temperature of 17 °C, for example. Effectively, the heating system is switched off for this purpose, since a Passive House building cools down only slowly and does not reach this level within just a normal weekend. Back-up operation usually only becomes effective on the third or fourth day of interruption of use, i.e. on long weekends or during vacation periods. Heating is then only necessary again for heating up before the start of operations. This intermittent use results in a diurnal dynamic with the highest heating output demand in the early morning, which declines as the day progresses and often reaches a marginal limit around noon. This effect is particularly pronounced in schools and other buildings used by many people, and results from the use-related heat generated by the presence of many people, artificial lighting and computers etc.

For optimised operation of the heating system, exactly the required output should be available in each situation, just matching the output requirement of the building. A minimised temperature of the medium can significantly influence the coefficient of performance of a heat pump and also reduce fluegas losses in a condensing boiler. Due to the steep increase in Carnot efficiency at low temperature differences of the heat pump process, any improvement here tends to have a significant effect.

In order to achieve a thermodynamic advantage at the heat generator, the forward flow temperature should never be controlled via return flow addition/mixing. Instead, the generator should always provide only the required temperature. Unless there is a particularly high demand for hot water, decentralised hot water generation with electric instantaneous water heaters is often a favourable solution in non-residential buildings and avoids a driver for high temperature in the main heating system. But even in centralised systems, the heat generator should provide high temperatures only for a short time for hot water generation.

The simple and generally established control of the heating medium temperature is based on the outdoor temperature using a control curve. It is not suitable for Passive Houses since due to the high thermal time constant of the building and the large influence of free heat, only a very weak correlation of the heating output with the outdoor temperature remains. Since many heat generators do not have an alternative control option, in the past the only easy possibility here was often a setting of the control curve that was as flat as possible and sufficiently shifted up in order to provide a quasi-constant flow temperature. Thus the possibilities of adapting to the demand remain unused, of course.

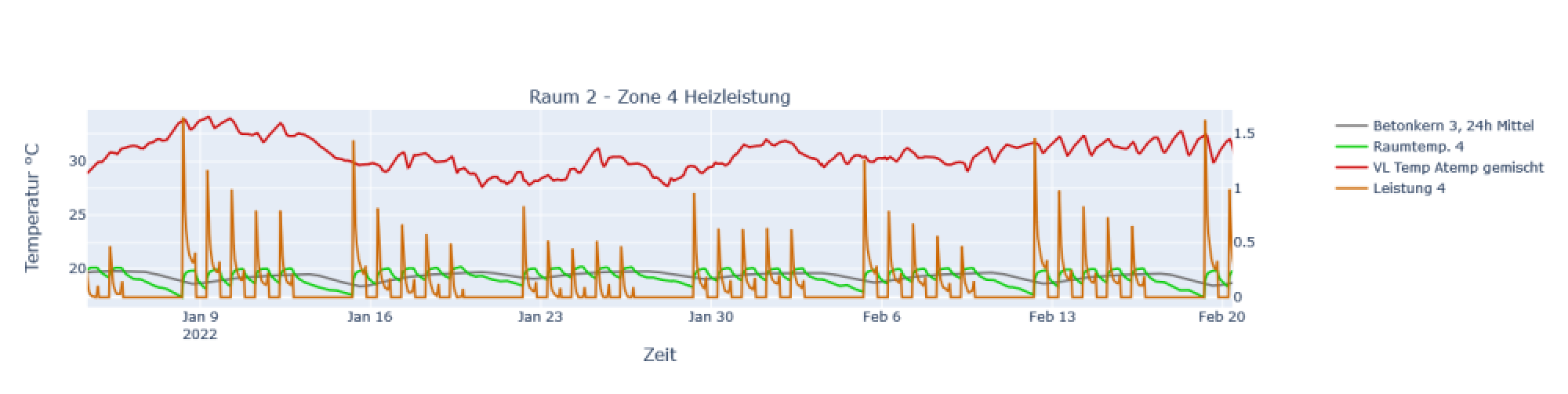

In the illustration above, the flow temperature setpoint (red) is controlled quite conventionally according to a control curve based on the mixed outdoor temperature. The correlation with the actually required heating output (orange, right axis) is often inconsistent. In some time periods, the forward flow temperature appears higher than necessary (e.g. regularly in the second half of the week), whereas in the heating-up phases after the interruption of operation at the weekend it is sometimes likely too low.

If the thermal condition of the building is known, it can be used as an input value for the control curve of the temperature of the medium. This already leads to a much improved correlation with the actual output demand. In its simplicity, this improved control curve method is certainly not optimal: short-term heat gains, especially from solar radiation, cannot be directly compensated. However, if the heating system is also switched off for the rest of the day when the pump speed falls below a minimum, i.e. when the flow rate is marginal, even this simple approach can work well.

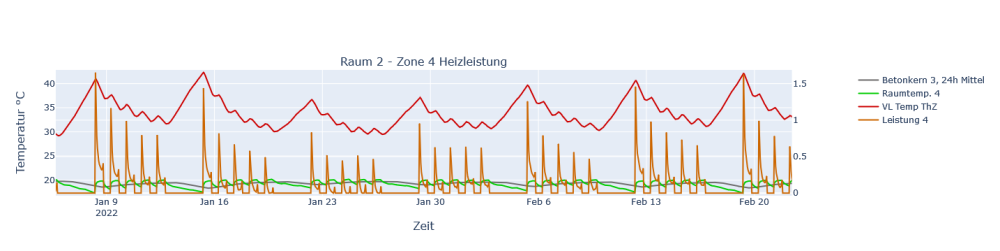

The second figure shows an example of the flow temperature setpoint (red) determined according to a control curve based on the thermal condition (grey). The required heating output is plotted at the bottom in orange, with reference to the Y-axis on the right. Compared to the outdoor temperature-related approach in the previous figure, a significantly improved correlation of the provided system temperature and required heating output can be seen. This already appears quite promising as long as the heating system is switched off during the weekends.

True output-based control that always provides only the minimum forward flow temperature for supplying the critical room is ideal. It must be assessed in each individual case whether the additional effort compared to the characteristic curve method based on the thermal condition justifies the expense. Possibilities here include regulation according to the measured heating surface temperatures, valve positions of the thermostatic valves or the cooling rate of the heating water, which usually requires some additional effort for data acquisition. The upturn in electronic data collection and transmission offers far-reaching new possibilities here, which should, however, always be evaluated against the background of reliable functioning over decades.

Ventilation system

In a Passive House building, the ventilation system with heat recovery (HRV) should be considered part of the building envelope: the hygienically necessary outside air is heated by means of the used air which is to be removed, so that up to 90% of the heat is retained in the building. In residential buildings, the ventilation system should be operated continuously, at least during the cold season, in order to provide fresh air even after short periods of absence. In non-residential buildings such as offices and schools, the ventilation system should be switched off in the evening and at weekends when people are going to be absent for longer periods according to schedule. Attention should be given to controlled shut-down mode with filter drying. However, a sufficiently long pre-purge phase should be adhered to before users arrive, which is typically approximately 1 hour.

Volume flow balancing

Besides the operating times, balanced operation of the system at all times and compliance with the planned volume flow rates must be ensured. Balancing is best monitored directly in the unit by measuring the volumetric flow at the fans and adjusted through sequential operation of the extract air fan in relation to the supply air fan (“master/slave”). Independent constant pressure control of both duct lines is too unreliable due to the cumulative inaccuracy of volume flow controllers. The current total volume flow must be visible in the automation system at all times and the setpoint must be editable.

Frost protection of the heat exchanger

In a ventilation system with heat recovery, frost protection has the task of ensuring that the volume flow can be maintained continuously even if the air drawn in from outside is so cold at times that the moisture could freeze over on the extract air side of the heat exchanger. However, the warm and humid extract air has the potential to prevent frost inside the heat exchanger down to an outside air temperature of typically -5°C. Ice formation on the extract air side should be expected only below this temperature. To stay on the safe side, it is recommended that the switch-on threshold for frost protection preheating should be set to about Toutdoor air ≤ -3°C. Higher switching temperatures would mean squandering some of the heat recovery potential and considerable unnecessary energy expenditure for frost protection.

It should be noted that for optimised control initially temperature sensors with a low measurement uncertainty are required. In general, the following applies as a recommendation for the control strategy for frost protection of a ventilation system in a building: frost protection should only be enabled by the building automation system when Toutdoor air is < 0°C. According to the above statement, frost should never be expected on the extract air side above this temperature because the extract air with its humidity brings some heat with itself. Furthermore, the following recommendations apply for the switch-on threshold of various heat exchangers:

| Type of heat exchangerr | Typical frost threshold |

|---|---|

| Rotary heat exchanger (regenerative) | Toutdoor air = -15°C |

| Recuperative heat exchanger without ERV | Toutdoor air = - 3°C |

| Recuperative heat exchanger with ERV | Toutdoor air = - 8°C |

Control units for frost protection are usually part of the manufacturers' control devices and are therefore not known in detail. This makes optimisation of operation beyond switching thresholds difficult or impossible. It is therefore at least helpful to discuss the problem and present a generic control strategy.

The following reference variables are possible for regulation of the frost protection preheating:

- Textract air on its own is too inexact because the variance of the temperature distribution inside the duct is too great

- Tsupply air on its own cannot reliably recognise frost formation

- Toutdoor air is unsuitable because the waste heat of the extract air is not included in it.

- For this reason, using a combination of Tsupply air and Texhaust air is recommended as reference variables.

One suggestion for the combined switch-on condition could be as follows:

Texhaust air < + 5°C and Tsupply air < 16°C

A low measurement uncertainty of the temperature sensors must be ensured, e.g. ±0.3 K incl. the measuring chain. In addition, the position of the sensors in the air duct is critical because of possible inhomogeneities of the temperature distribution. Experiences gained in laboratory tests with frost-protection show that with Textact air < + 5°C , ice may already have formed to a considerable extent. Each manufacturer must develop an adequate frost protection strategy and adapted control strategy for their devices. The parameters and threshold values mentioned here are only reference values. Significantly improved transparency with regard to the strategy implemented in each case would appear to be advisable.

Frost protection itself can be achieved with several different techniques, which are only briefly mentioned here.

- Preheating of outdoor air

- Electrically

- Hydraulically from the heating system

- Heat exchanger

- Ground-source brine circuit

- Supply air recirculation. Heated supply air is mixed with the outdoor air in order to raise the temperature. The filters must be allowed to dry before a ventilation system can be shut down in the evening or before the weekend. Supply air recirculation can also be used for drying the filters.

- Outdoor air bypass. Maintains the overall balance of the unit and achieves an extract air surplus in the heat exchanger. Requires post-heating coils for maintaining a minimum supply air temperature for thermal comfort reasons.

- De-icing by means of sectional disbalance in the heat exchanger (requires special control elements)

A reduction in the supply air volume flow to prevent icing over in the heat exchanger is not recommended for hygienic reasons. If a building is not primarily heated via the supply air, then the supply air volume flow can also be reduced to a certain extent. It should be noted that in such cases forced infiltration causes an increase in the heating load, which must be accommodated additionally.

Control of the supply air temperature

Conventional buildings or even existing buildings with a lower standard of insulation in which ventilation only takes place with cold outdoor air via windows are thermally 'unstable' and cool down to uncomfortable temperatures within a few hours as soon as the heating is switched off or breaks down.

On the other hand, buildings are generally thermally 'inert' due to their large mass, i.e. heating-up processes, for example after window ventilation or after a night-time setback can therefore only be realised with time constants of a few hours, even in old buildings. For this reason, the room temperature must be maintained at a specified setpoint, e.g. 21°C, with the help of possibly complex control algorithms. Overshooting of the temperature is particularly problematic for control algorithms: if the heating output is increased linearly (proportional controller) depending on the difference between the room temperature and the setpoint, then after reducing and switching off of the heat output, the room temperature will usually rise above the setpoint and 'overshoot'. Additional integral or differential control components may also only inadequately prevent overshooting. This problem is well known in control engineering and is described in detail in the relevant textbooks, so it will only be briefly mentioned here. In buildings and with regulation of the room temperature, another control task arises when additional disturbance variables with possibly shorter time constants have to be taken into account, for example when window ventilation or a ventilation system (without heat recovery or with poor heat recovery) brings cold air into the room. Frost protection of heating coils must also be realised internally via adequate control in ventilation units with air heaters. Such control tasks can be solved with nested control loops (cascade control). An example of cascade control: the room is heated via heating surfaces. In addition to controlling the room temperature depending on the extract air temperature, it is also possible to directly observe the disturbance variable supply air temperature from the ventilation system. The supply air temperature controller with a temperature sensor in the supply air duct can directly affect additional heating of the supply air and thus correct cooling down in the room faster than would be possible with the extract air room temperature controller, which would only control the heating surfaces when the extract air temperature had dropped accordingly.

However, it turns out that these control concepts often deal with control tasks that are either not needed in Passive House buildings or even contradict the Passive House concept. In a Passive House building, ventilation with high-quality heat recovery ensures that the supply air is kept at a comfortable temperature ≥ 17°C all throughout. In addition, in Passive House buildings the internal heat sources (IHG) can contribute to heating of the rooms to an appreciable extent. Furthermore, the room temperature within the range of 20 to 25°C is considered as comfortable. This means that if the room temperature is within this range, neither heating nor cooling is required. It is well known from monitored projects that many users find a temperature of 22°C to be optimal.

Assuming this, the above example shows that a simple control system for supply air post-heating, which keeps the supply air temperature at a constant TSUP = 21°C is not suitable for a Passive House building: With the thermally well-insulated building envelope and especially airtightness and the heat recovery ventilation system for the Passive House building, building characteristics exist which basically keep the room temperature and thus thermal comfort in indoor spaces at a constant level. The thermal inertia of the building is so great that short-term, spatially limited temperature fluctuations, e.g. due to a rare open window are quickly buffered away. If there are radiators the supply air in the Passive House building does not need to be heated any further apart from the frost protection pre-heating described above. The minimal supply air temperature of 17°C is sufficient and in this way good use can be made of the temporary IHG and solar heat gains ('free heat'). However, if the supply air is always (expensively) kept at 21°C, this often leads to undesirable overheating of the rooms, which the users may ventilate away via windows unless the heat recovery is already automatically regulated in the unit. In both cases, however, the use of free heat is prevented and the Passive House concept is counteracted.

The control task must therefore be defined differently and is even much easier in a Passive House building: the comfortable range is TRoom = 20 to 25°C or possibly 22 to 25°C if desired by the users, e.g. in nursing homes. A (temporary) increase in the room temperature within this range due to free heat can be acceptable and is usually even desired. This is because heat gains during the day can and should be deliberately stored in the building mass. Over-sensitive regulation is not only costly, but is usually also counterproductive: thus (in winter) the bypass function of the heat recovery system must not be activated under any circumstances in order to keep TSupply air at 21°C, and cooling must not be used at all. Instead of a fixed value for the supply air temperature, the room temperature should therefore be observed as a control variable in the Passive House building. In non-residential buildings, the extract air temperature or a suitable average value obtained from both can also be used. Of course, very high IHG must be considered and controlled separately for zones with special uses. The thermal condition of the building may provide information as to whether gains from free heat are desirable or should be avoided at a given time. If this is not available, Toutdoor air < 16°C (comfort criterion) for more than 7 hours per day may serve as an alternative criterion for winter operation with full heat recovery. If a purely calendar based solution is to be implemented (which cannot respond to unusual weather conditions, but is usually correct), a decision can be made based on the monthly mean values of the outdoor air temperature [AkkP 44]. A similar approach is also conceivable based on measured weather data using a moving monthly average.

It is important to note that the 'winter' period defined above is significantly longer than the heating period in a Passive House building. This is because in the transitional period (around April to May and September to October) with moderate outdoor temperatures, ventilation with HR is important to ensure comfortable supply air temperatures. On the other hand, it may also make sense to activate bypass operation on individual days and hours with TODA > 25°C. Measurement of the temperatures in the fresh air, extract air and exhaust air ducts and a corresponding control mechanism with the control unit of the ventilation unit can be used for this purpose. Again, transparency relating to the algorithm used is important for commissioning and optimisation of operation.

Shading

Movable shading elements are particularly conspicuous to building users and their (noisy) movement is often perceived as annoying. In addition, individual preferences of different users must be balanced with operation of the shading appropriate to the season. Well-designed control and regulation is therefore of particular importance for user acceptance and building function alike.

Depending on the thermal condition of the building, solar heat gains are either desirable or to be avoided. Seasonal differentiation (determination of the seasonal operating mode) is therefore absolutely necessary. If solar gains are desired, the movable shading device will normally remain open. However, a possibility for user intervention is urgently required for the reasons mentioned above in order to take into account different preferences or requirements. It has proven effective to allow such user interventions for a limited time and then revert to the automatic signal again. A period of 2-3 hours avoids excessive patronising of users, but also ensures proper building operation.

If solar gains are to be avoided, the shading device is normally closed when a threshold value for irradiation of approx. 150 W/m² (global radiation, ~ 15 kLux) is exceeded on the plane of the façade in question. On the other hand, user intervention is again possible at any time for a limited period of time.

If automatic operation is deployed again at fixed times then a schedule of 06:00, 09:00, 12:00 etc. may constitute a reasonable framework.

It always makes sense to split control of the shading devices at least with regard to the storey and orientation. If there is shading of the façades from neighbouring buildings, a critical elevation angle can also be included. Solar position algorithms used in shading controls supply the actual value.

The selection of a shading system that provides sufficient daylight is an additional planning aspect.

Regulation should be based on measured values from a high-quality sensor that is calibrated in an appropriate manner. Only then can reliable functioning be expected in the long term. A global radiation sensor (horizontal) is appropriate in case of operations monitoring, the measured values can then also be processed into monthly values for irradiation at that site.

Sustainable operation

Operation of the building automation system is embedded in the long-term management of the relevant building. Through flawless functioning it should permanently provide the benefits being strived for, and should contribute to the optimised use of resources. Both can be summarised under the term sustainability, at both the technical and ecological level. The ecological side itself may comprise different facets and also overlaps with the technical aspect of sustainability.

The efficiency of the automation system is of great importance here, expressed by the (absolute) benefit in relation to the effort required for it. This may be directly related to the ratio of the auxiliary energy demand and the achieved energy savings, or also to the use of resources for the production of a system and its technical lifetime. The latter is also directly linked to the reliability or functional quality of the system.

In short, what matters is achieving the highest possible benefit with the lowest possible use of resources. This means a very low auxiliary energy demand in robustly functioning systems with a long service life (> 20 years). Robustly functioning systems can be achieved if suitable concepts are pursued.

Auxiliary energy

In the current discussions about the growing importance of building automation, the auxiliary energy demand required for the operation of these systems is rarely mentioned. In this respect a simple measurement of example components shows that a considerable amount of energy is used here.

A large number of actuators, sensors and automation controllers (PLC) use electrical energy to perform the desired function. The respective power requirements appear to be low at first, many values are just a few watts. However, over the large number of elements the auxiliary energy demand adds up to a considerable amount. This effect can also be proved time and again through field measurements and appears as a substantial contribution to the standby power consumption of the building remaining outside the times of use. In a sample of larger non-residential Passive House buildings in Germany, more than 12 kWh/(m²a) was expended for the area in question. This value corresponds roughly to the useful energy consumption for heating energy or half of the use-related electricity consumption in an administrative building. This is therefore an area that must be taken very seriously, and a reduction in the auxiliary energy demand of automation systems seems to be urgently needed.

Since non-residential buildings are usually operated intermittently, large parts of the automation system can, in principle, also be switched off during the downtime. This would already result in considerable savings.

Furthermore, a fundamental improvement in the energy efficiency of the building automation components used would also be strongly desirable. The selection of more efficient power supply units that are better adapted to the consumers already holds great potential. The installation of a separate low-voltage network (24 V) in combination with high-quality, well-utilised power supply units is also a helpful approach. The preliminary work on energy labelling carried out within the framework of the Ecodesign process at the EU level has not yet been completed (2023). It remains to be seen whether ambitious specifications can be implemented here. The specifications must be based on a budgeted approach depending on the respective range of functions of a device.

The table shows what exemplary classification could look like.

| Efficiency class field device | Power requirement inc. power adapter per measured value/switching value/control variable [W] |

|---|---|

| A+ | 0.03 |

| A | 0.1 |

| B | 0.25 |

| C | 0.5 |

The measurement of a parameter, calculation of a control loop and output of the control signal, switching of a consumer and digital communication with a network or management system (BMS) can be taken into account here. An evaluation methodology with an emphasis on efficiency that is realistic and easy to use should be developed for this purpose.

The development of smartphones has proved that high processing capacity can be made available when required and that outside these times, extremely energy-efficient operation with battery supply is still possible. The relevant technologies are therefore available and would only have to be adapted for automation stations. For communication in a complex (IP) network and remote configuration of automation stations, significant processing power may be necessary temporarily, while the computation of common control loops has minimal requirements. The periodic collection of measured values is even less demanding.

Switching on electrical loads

Relays for direct or indirect switching of loads play an important role in the use of electrical energy in automation stations. A continuous flow of current in the magnetic coil (equating to ~0.2…1 W) is necessary for switching on of the operating contact. Since many loads in buildings remain switched on over longer periods of time (e.g. pumps), a significant amount of energy is used here and unwanted heat may also be produced. In contrast, the usual relays are low-cost, reliable and revert into a defined state in case of a power failure. Improved efficiency when using conventional relays is easily possible by lowering the coil current after switching on – simply stopping the magnet keeper/ armature does not require the full current. This can be done flexibly by operating with pulse width modulation (PWM) or even by simply wiring with a serial resistor and a parallel capacitor, which can already save more than 60% of the energy consumption for the relays. The somewhat reduced vibration tolerance is of little relevance for applications in buildings. Another option is to use bistable relays, which are switched by current pulses but then maintain the switched state without current. They are more expensive than the usual, monostable relays, but consistently reduce energy consumption to a minimal amount.

Electronic relays (solid state relays) can be switched almost without power and have no moving parts. They also revert to a defined state in the event of a power failure and can change their switching state several times within a second. Even so, they are less interesting for building automation because they have a power loss of a few percent of the load. They therefore convert a considerable part of the switched current into heat and accordingly require a heat sink. Upcoming generations of semiconductors based on silicon carbide are expected to significantly reduce these losses. For long-term switched loads, however, the fundamental advantages of mechanically switched relays remain in place for the time being.

Actuators

For actuators of all types, the standby or hold state is usually decisive for the efficiency evaluation. Actuation processes are rare and only take place slowly. The energy requirement for a full actuation process should nevertheless be known in order to be able to estimate the energy consumption for a specific application.

When operating pumps and fans with an EC motor, it should be noted that the shutdown is not merely a result of a “0 V” control signal, because the power electronics have a significant standby power consumption. Disconnection from the mains is a better alternative. Adaptation of the pump power to the demand, for example by means of pressure regulation or flow control, is already common today and should always be used.

Room control units

For room control units, similar guidelines apply as for the automation stations controlled by these: for most of the time, these are not active and must therefore be equipped with effective power saving mechanisms. Processors should adopt corresponding deep-sleep states; a substantial part of the power is used for increasingly larger colour displays. These are only given attention and used by room users after longer intervals. Small monochrome LCDs are more advantageous here. Large-scale E-ink displays can also be used and also look attractive. They only use energy when the display changes and do not need any backlight. New developments with this technology allow for multi-coloured and even colourful displays.

Network

Interconnectivity of building automation components is an essential prerequisite for functioning as a system. The amount of energy used for operation of the connected components (storey distributors/switches etc.) is considerable. Both the investment costs as well as the operating costs for the systems are significant, even though building automation systems have low bandwidth requirements for the most part. It therefore makes sense to integrate the building automation into the physical IP network infrastructure which is already necessary in any case in order to achieve a high level of utilisation of the system instead of having to operate two systems in parallel.

Waste heat

Secondary effects also arise with improved efficiency of the building automation components. The lower operating costs with the reduced power consumption are obvious, but planning and execution can also become easier with lower heat loads. Switch cabinets do not have to be ventilated or even cooled, and a more compact design becomes possible. The service life of electronic components is also extended as the surrounding temperature falls.

The guiding principle for new development could be: “Every circuit should be designed as if it were powered by batteries, and one should learn from mobile devices”.

Measurement uncertainty

An appropriate measurement uncertainty must be complied with for each measurement task. In order to be able to evaluate this at all in individual cases, the measurement uncertainty must first be specified. This is currently not common in building automation and information is difficult to obtain. Often, only the classification of the sensor is given; for example, for a platinum resistance thermometer “Class B according to EN 60751”. However, this information has no meaning for the measurement uncertainty achieved, since the entire measurement chain consisting of the sensor, measuring lines, constant current source, reference voltage and A/D converter is included in the overall uncertainty.

For precise determination of the thermal condition, if it is to be applied for individual rooms or smaller room groups, and for checking the actual energy consumption, a measurement uncertainty of ≤ ± 0.3 K is required for the entire measurement chain in the temperature measurement. The class VDI/VDE 3512 A-TGA (based on a resistance thermometer Class A or AA according to EN 60751) should thus form the standard design, and for special cases an improved class “AA-TGA” (Class AA EN 60751 and improved measurement electronics for only half the measurement uncertainty) should be offered in an easily accessible form (for example for special control tasks in concrete core temperature control).

High-quality sensors exhibit low drift with changing ambient temperatures and over the course of time. Nevertheless, all measuring circuits change their characteristics, which is why a ratiometric measurement is to be preferred. A reference resistor is available for this, which can be regarded as almost invariable if the quality is appropriate. The measurement of the platinum resistance temperature detector (RTD) is then always carried out in direct comparison to the reference resistor, all variations in the excitation current or the reference voltage at the AD converter are thus compensated. Measuring bridges for precise monitoring of temperature differences with two platinum measuring resistors can also be a helpful addition to the building automation repertoire.

Even with a high quality of implementation, at least a random check of the measurement uncertainty should be carried out at regular intervals. For this purpose, the organisational prerequisites must be created during planning and execution, such as clarification of responsibility and a budget. For all measured variables within a building automation system, it should be possible to store and edit at least the factor and summand for calibration in a simple and comprehensible manner.

The same applies for sensors for relative humidity (typical measurement uncertainty ± 2 to 3 %). Particularly high reliability of the measurement usually isn't necessary in Central Europe; nevertheless, excessive deviation should be detected and corrected in time. An aspiration psychrometer or a dew point mirror provide a reasonably reliable reference for this. Special care should be taken if CO2 sensors are used. Inexpensive sensors, such as those used for building automation, always exhibit a considerable drift due to their design. Regular calibration is therefore absolutely necessary in order to maintain the already comparatively large measurement uncertainty of around ±70 ppm and to avoid even greater deviations. If the sensor does not include suitable equipment for automatically carrying out such corrections, it should not be used, since annual recalibration is hardly feasible and very cost-intensive.

Modern CO2 sensors include a mechanism for self-calibration based on the minimum value within a 10-14 day measurement period. By implication this assumes that within such a period the outdoor air concentration occurs due to abundant ventilation without occupants in the room. For common non-residential Passive House buildings with intermittent operation of the ventilation system, this state should occur during the pre-purge phase at the beginning of each day of operations. This mechanism can therefore reliably take effect here, unlike in residential buildings for example, where there is strong dependence on the habits of the respective occupants.

Irradiation sensors play a special role in Passive House buildings. At present, brightness sensors based on very inexpensive photodiodes are used to control shading systems. A separate diode is provided for each cardinal direction, protected by a simple plastic housing. This technical standard is insufficient and is not reliable over longer periods of time. All individual diodes have slightly different characteristics due to production and also age differently. In addition, the plastic cover becomes cloudy over time, which also causes a permanent change in the characteristics, apart from accumulation of dirt.

Reliable operation of the shading system cannot be assured on such a basis, and control parameters once set must be adjusted later to compensate for aging/clouding of the sensors. It is also not possible to obtain reliable radiation readings for operational analysis as desired for energy-efficient buildings. It therefore appears expedient to strive for higher standards of radiation measurement in the future. Calibrated and temperature-compensated PV reference cells with glass covers in combination with a high-quality measuring circuit have the potential to be a low-cost alternative. With such sensors, horizontal global radiation of a sufficient quality is then available for control of shading and operational analysis. From the measured value, the irradiation on randomly oriented surfaces (e.g. façades) can be determined with the aid of a sky model and used as an input value for regulation.

Durability of the automation system

Buildings are among the longest-lived capital goods; the life cycle can easily exceed 100 years. For components of the building envelope, a useful life of 40 to 60 years is common, while technical equipment can last 20 to 30 years. Building automation systems should also achieve a useful life of more than 20 years to ensure ecologically sustainable and cost-effective operation. Manufacturers should indicate the constructive service life in product documentation. Without reliable information about the technical life duration, it is impossible to make a serious economic assessment. To achieve a long service life, certain critical components should be avoided or only used in a selected quality (e.g. batteries, electrolytic capacitors).

To a considerable extent, the permanent functioning of a building automation system is also influenced by the hardware and increasingly, the software, of a management and operation level. If proprietary software is used, software updates may no longer be available within the service life being strived for (e.g. 20 years), or security updates may no longer be offered for the underlying operating system. For reasons of IT security alone, such a situation would be unacceptable, forcing a time-consuming and expensive change of hardware and software plus the effort for their setup. Dependence on one single supplier should also be limited.

Thus either open standards for measured values and operating states from the past, as well as their representation are required in order to make software solutions from different providers or software generations directly compatible. And/or a free open-source development supported continuously by the users themselves should be initiated (e.g. for public buildings, throughout Europe). This could be available for decades and its range of functions could be continuously adapted to the needs of the users over time, without having to take marketing interests into consideration. It could also be made available for different platforms.

Interconnectivity of information in building automation has potential for optimised operations management. At the same time, practical experience shows that only comparatively simple, robust concepts can provide permanently satisfactory functioning. Constant consideration and, in case of doubt, opting for the simpler variant is necessary here. A critical analysis of possible interruptions in the information chains and their consequences is required, combined with precautionary measures for the respective case. At the very least, emergency operation with clear error messages should always be guaranteed.

See also

Building automation for energy-efficient buildings

More detailed information can be found Protokollband 59 (German)