Insulating the basement ceiling

The basement ceiling can be insulated from underneath or from above; generally speaking, it is easier to insulate from underneath because there will be no mess in the living area and it will not be necessary to clear the space for the work.

This kind of basement ceiling insulation does not pose any risk in terms of building physics: this is an external side of the indoor space and the temperatures are all more in the moderate range. The basement will usually become colder as a result; however, this is often expressly desired.

Caution is necessary if there are combustible materials in the basement: only non-combustible insulation materials are possible in the case of an underground garage or oil storage. Otherwise practically all commercially available insulation materials may be used as long as these can be affixed to the ceiling without any gaps. Of course, the wishes of the building owner and users with regard to the appearance of the visible surface after the measure also plays a role.

Solution with composite panels

Composite panels here also allow for an underside that can be painted over; but some effort will also be required for applying filler and plugging/filling at the edges. It is easier to apply the composite panels on an even underside of ceilings. If the ceiling is not level enough for direct application with adhesive, then it is also possible to attach these panels by screwing them on supporting slats/battens/lathing: in this case any resulting empty spaces must then also be filled with insulation, see further below.

Insulation matting and new ceiling panels

In the case of uneven ceilings or ceilings with many pipes, softer insulation matting can be attached more easily to the ceiling using e.g. insulation dowels. For example, lightweight cement-bonded wood wool panels (or some other type of panel) can be attached using screws, and can then be plastered over easily.

Loose-fill insulation

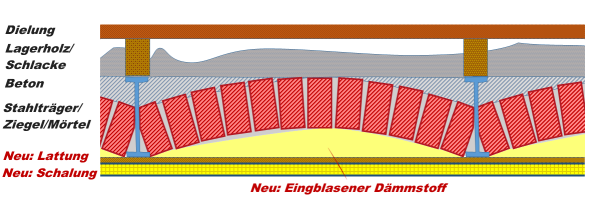

The wood wool panel (or any other type of panel) can be applied under the ceiling at some distance 1) and the resulting hollow space can then be injected with blown-in insulation, in which case any pipe attachments, cable ducts etc. will be less of a problem. This method is particularly suitable for ceilings that are less even (e.g. old vaulted ceilings).

Caution! Gas pipes must not be “built-in”/incorporated; these must therefore be walled in by the ends of the insulation panels, or the gas pipe can be decommissioned – in any case, the use of fossil fuel gas doesn't have a place in the future 2)

What to do with little space?

It is often the case that there is limited space under the basement ceiling. If this is the case, then insulation materials with very low thermal conductivities, such as phenolic foam sheets or even vacuum insulation panels, are recommended (and are also worthwhile). (Caution! Of course, these CANNOT be cut and in any case must be handled like raw eggs).

Basement ceilings frequently have installations, cable ducts etc. running along these. Ultimately it is almost always easier to suspend these a bit lower than to laboriously work around them; and anyway, these usually have to remain accessible. The alternative is to use loose-fill insulation as already described.

As always with thermal protection, 'a little is good, more is better'! In a basement this is usually restricted due to the already low room heights, but even small insulation thicknesses offer some benefit; however, in that case insulation materials with an extremely low thermal conductivity should then be used (λ≤ 0.025 W/(mK) is available without problem today). Such insulation panels with an extremely high insulating effect are appropriate in cases where the space is limited, also as expendable/permanent formwork for the blown-in insulation described above.

A positive “side effect”: warm feet! Cold floors on the ground floor are often especially uncomfortable.

Another positive “side effect” is that the old floor build-up will now become significantly warmer and will also be better protected from the basement air. This also has the effect of improving protection of the building substance.