Table of Contents

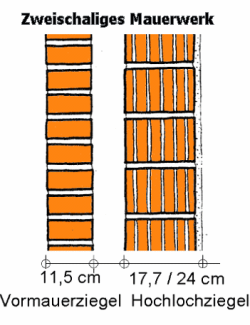

Insulation of double-leaf/cavity walls

“Cavity insulation” describes the filling of intermediate space between the outer leaf (facing wall) and the inner leaf (load-bearing wall) of what is known as a double-leaf or cavity wall.

“Cavity insulation” describes the filling of intermediate space between the outer leaf (facing wall) and the inner leaf (load-bearing wall) of what is known as a double-leaf or cavity wall.

A cavity wall is a type of wall construction that is traditionally used in the northern region of Germany. The well-proven building physics concept of “double leafs for weather protection” has been brought to perfection here:

- The main function of the outer masonry leaf (facing wall) is to serve as protection against driving rain and drifting snow - outdoor air flows behind it (thermal bypass) so technically it stands in the cold. In terms of material and structure, it can be designed so that it is free-standing and can resist all weather conditions that may arise. Nevertheless, moisture which can still penetrate the outer wall into the air cavity no longer finds any capillary-conductive material here, in the worst case it can saturate the air layer to a relative humidity level of almost 100 %, but it regularly dries out again due to the thermal bypass. The load-bearing wall is always a bit warmer than the air in the intermediate space due to heat flow from the inside - therefore this load-bearing masonry wall can no longer absorb a high amount of material moisture 1).

- The air space that is (often very carefully) ventilated from outside also removes towards the outside any small amounts of water vapour that may have entered. It is apparent that air flow behind is not even particularly critical here; the fine cracks in the mortar of the outer leaf that are usually always present are already enough 2) . Likewise, it is entirely unproblematic if such an intermediate space is filled with a material that is not capillary-conductive and diffusion-permeable (µ < 2) 3) .

- The inner leaf is the actual load-bearing wall. It is perfectly protected by the outer wall from the effects of the weather. As a rule, only heat can still be conducted through the inner leaf towards the air space, so improving thermal protection here is often worthwhile, either from the inside or by filling the air space with a suitable insulation material.

This construction has better sound insulation characteristics in addition to protection against the effects of the weather. Apart from this, this kind of assembly is practically indestructible unless completely unsuitable material has been used for the outer wall; such a façade has to be cleaned two times in a hundred years if it becomes necessary. If insulation is added inside the cavity wall and/or on the inside, none of these advantages will be lost - on the contrary, they will become even better. Because this is also offered at a low cost by specialist contractors, we can only strongly recommend the measure described here.

Cavity insulation

For cavity insulation, the air gap between the two walls as described above is injected with insulation material. The building owner commissions a company specialising in this kind of work; we advise you to contact the (German??) association for cavity insulation specialists. The procedure is as follows:

Apart from the preliminary inspection which can be done at any time, filling of the cavity by an experienced team takes less than a day for a typical deatached house with cavity walls – good teams leave neither a mess nor any destroyed flower beds behind 4). Different teams apply somewhat different methods in which they are experienced; the client can choose the method that is suitable from among the contractors.

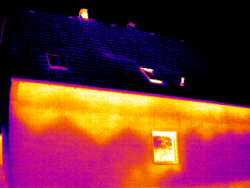

Checking with thermographic imaging is easily possible afterwards because the masonry will become more homogeneous due to the cavity insulation if executed correctly. Any defects will be easily visible in the IR images, but here we also recommend that a professional thermographic imaging expert should be consulted because misinterpretation (warm spots due to sunlight, shading of IR emission) may otherwise often occur with inadequate knowledge of the physics of heat radiation. In the example image on the right, the heaps????? of filling material can be seen, below which the insulation material is already present; the yellow area above this is not filled yet.

Checking with thermographic imaging is easily possible afterwards because the masonry will become more homogeneous due to the cavity insulation if executed correctly. Any defects will be easily visible in the IR images, but here we also recommend that a professional thermographic imaging expert should be consulted because misinterpretation (warm spots due to sunlight, shading of IR emission) may otherwise often occur with inadequate knowledge of the physics of heat radiation. In the example image on the right, the heaps????? of filling material can be seen, below which the insulation material is already present; the yellow area above this is not filled yet.

Evaluation in terms of building physics: if a suitable insulation material (not capillary-conductive, less prone to subsidence, moisture resistant) is used, then the situation will only always be improved from the building practice point of view - even if some areas cannot be filled or are only incompletely filled (but a professional company will always still take care of that). Because insulation takes place on the outside of the load-bearing and airtight wall, its temperature is raised across the entire cross-section 5). This increases building preservation – the risk of condensation or increased moisture in the supporting wall is thus decreased. Noise protection is usually also improved. The heat losses of the wall decrease in accordance with the additional thermal resistance Rplus of the insulation, which in turn is proportional to the thickness of the air layer d divided by the thermal conductivity λ of the insulation material that is used. Since such a measure only makes sense with a thickness of 3 cm or more (approximately 50 % reduction in losses with the improved wall), and there is also a distance of 11 cm between the walls (about 75 % reduction in losses through the wall); a significant saving is achieved with this, even though this measure on its own does not give a peak value for the insulating effect. Of course, this measure can be improved even further with additional insulation on the inside 6) ; this is facilitated due to the protective effect of the cavity insulation in this case: entry of driving rain can be ruled out and the risk of condensation inside the building assembly is greatly reduced on account of the blown-in insulation which is on the outside of the load-bearing wall.

Evaluation in terms of building physics: if a suitable insulation material (not capillary-conductive, less prone to subsidence, moisture resistant) is used, then the situation will only always be improved from the building practice point of view - even if some areas cannot be filled or are only incompletely filled (but a professional company will always still take care of that). Because insulation takes place on the outside of the load-bearing and airtight wall, its temperature is raised across the entire cross-section 5). This increases building preservation – the risk of condensation or increased moisture in the supporting wall is thus decreased. Noise protection is usually also improved. The heat losses of the wall decrease in accordance with the additional thermal resistance Rplus of the insulation, which in turn is proportional to the thickness of the air layer d divided by the thermal conductivity λ of the insulation material that is used. Since such a measure only makes sense with a thickness of 3 cm or more (approximately 50 % reduction in losses with the improved wall), and there is also a distance of 11 cm between the walls (about 75 % reduction in losses through the wall); a significant saving is achieved with this, even though this measure on its own does not give a peak value for the insulating effect. Of course, this measure can be improved even further with additional insulation on the inside 6) ; this is facilitated due to the protective effect of the cavity insulation in this case: entry of driving rain can be ruled out and the risk of condensation inside the building assembly is greatly reduced on account of the blown-in insulation which is on the outside of the load-bearing wall.

Costs and economic efficiency

The costs in each individual case will naturally depend on local circumstances. Most contractors for blown-in insulation materials can often provide this without any scaffolding work and in a “garden-sparing” way in the case of detached and semi-detached houses. As a rule, two visits are necessary: for “test drilling” from the outside and checking whether a cavity is present and how thick it is, as well as to see what it looks like inside. This is done using an endoscope. The actual injection process is completed in one day for such a building. Several contractors have confirmed that in practice, the cost is usually less than 24 €/m² (for a 5 cm cavity).

For an effective insulating layer thickness of 5 cm, the energy saving amounts to about 60% of the original losses of this wall; this is often 30% of the heat loss of such a building; in addition, as a result of this (and due to roof and basement insulation which will certainly be implemented at some time), the house becomes suitable for the installation of a heat pump.

With a saving of around 57 kWh/(m²a) this will then cost the homeowners 1.7 cents/kWh (!!) for each saved kWh of oil or gas. Hardly anyone will be able to obtain heating energy so cheaply anywhere in the future – oil-fired heating is now around 10 times this price.

In view of the lack of clarity in the funding situation, our calculations have been performed without taking into account any subsidies.