This is an old revision of the document!

Table of Contents

Life cycle assessments: Methods, criteria and data (availability) for assessment

This article is based on a paper published in the 58th volume of the Research Group for cost-effecive Passive House buildings on the topic of “ Energy-efficiency and CO2 emissions over the life cycle - Part 1: building materials and constructions”. The original article by Wolfgang Feist und Witta Ebel is availabe in German in the proceedings, which can be accessed here.

Benchmarks: Primary energy and CO 2

Here, we will focus on the energy application for space heating. The reason for this is: 1) In connection with buildings, space heating contributes the greatest to climate pollution. 2) The associated consumption is strongly influenced by the building (floor plan, envelope, construction, components and building materials). In contrast, other operating parameters in existing buildings can hardly be influenced by structural measures with reasonable effort (hot water consumption, electricity consumption for non-heating purposes).

We have identified and will use the following as benchmarks:

- Primary energy, namely renewable primary energy (PEr) that will ultimately be necessary

The PHI has recognised and introduced this parameter as a fixed assessment factor for the required energy expenditure for some time. It is the amount of renewable energy that must be generated to maintain the usual services of renewable energy systems. In contrast to “conventionally used, non-renewable primary energy”, this benchmark is not dependent on the fossil fuels that happen to be used and is therefore suitable as a benchmark in the first place [AkkP 56] [Feist 2014] [Grove Smith 2021] [Passipedia 2016].

Reasoning: this parameter determines the total expenditure for implementing the energy transition. The PEr costs vary for different heating systems (e.g. heating with hydrogen or heating with a heat pump). The same applies to different qualities of the building envelope. Both can therefore be assessed using the PEr scale on a uniform and time-independent basis.

- For the impact on climate: the GWP “global warming potential”

The GWP is a clearly defined value for the energy sources used. The GWP rucksacks of various materials are also documented in corresponding databases. Any deviations within such data and the typical uncertainty as well as methodological flaws in this context will be discussed in this article.

Reasoning: The GWP determines the dominant part of the environmental hazard. Of course, other variables are not irrelevant, but compared to the acute threats posed by climate change they are less important at present. However, in order to determine applicable GWP figures, an at least approximate scenario for energy generation over the next 40 years or so must be applied. The discussion on this is also part of this article.

Life cycle analysis

There is now (broad) agreement that the benchmarks must be applied to the sum of the respective variables over the entire life cycle.

Reasoning:

- The total emissions are important for the environmental impact

- If cycle costs are also the correct economic approach to maintaining and improving prosperity

What is included in the life cycle?

There are different views on this. We will explain here which approach we have taken and why; we include the following:

- Preparatory effort /advance performance/input for material (provided that this has not already been “counted” elsewhere, as may be the case with e.g. recycled material).

Reasoning: building materials are predominantly produced precisely for this purpose, namely for use in construction. The planned use is therefore the cause of the production of the material - and, in line with the polluter-pays principle, the expenses or emissions incurred in the process must therefore also be attributed to the building. \\These upstream chains include all the material, energy and construction inputs (“rucksacks”) that are included in modules A1 to A3 of the chain (“raw material sources to factory gate”) in accordance with the standard [EN 15978]; in addition, there are expenditures for transport, but generally these are not particularly high.

- Inputs for planning and building

Reasoning: Inputs clearly associated with the building and any pollution caused. Note: (see also further below) as a rule, these expenditures are of little significance for the ecological balance. 3)

- Expenditure during operation

Reasoning: Also clearly associated with the building and any pollution caused by the building. Note: As a rule, these expenditures are dominant for the ecological balance.

- Expenditure for deconstruction

Reasoning: deconstruction also takes place because of the present building and any pollution caused will therefore be allocated to this. We will discuss the scale of these expenditures in more detail in the course of this article.

According to our analysis, the life cycle does NOT include expenditures, effects or credits due to a more or less likely scenario for “subsequent utilisation”. It will only be different if this is a disastrous consequence without an alternative. However, the latter is generally not the case for materials used today in new constructions and retrofits (otherwise the use of such materials in construction would not be permitted).

Reasoning:

- The utilisation periods of all components typically used in construction that are relevant here (technical components are only dealt with in AK60) are at least 40 years. The subsequent utilisation that is ultimately selected therefore cannot be reliably determined today.

- Processing for a subsequent use then takes place with regard to the application in this subsequent use (e.g. generating energy for an electricity network or disinfection for re-use as a building material). The costs and pollution that are incurred must accordingly be accounted for in the respective subsequent use. This will then also be possible without problem because for the subsequent use the relevant costs and pollution are also known. This also applies, for example, if the subsequent utilisation consists of burning (the emissions are then to be allocated to the energy generation associated with this; however, as will become clear later, we do not recommend this), or if the subsequent utilisation consists of inert landfilling: in this case, the energy wastage of the expended grey energy for the object under consideration will take place correctly – no further emissions arise as a result of inert landfilling.

Time intervals: useful life of materials

The following principle will basically be used here with reference to the useful life:

Each material layer is primarily determined by the useful life of the material ageing there under the respective circumstances. An exception to this occurs if, for example, for the renovation of a render an exterior coat of paint becomes useless before time during its useful life. In this case, the usage period of such a coat of paint is reduced by that of the layer triggering the measure, so this is also taken into account in our calculations.

In the course of our work, it was found that with the exception of paintwork and popular styles of external cladding, all structural components in existing buildings predominantly have service lives of over 40 years; structural components that are of importance in terms of statics even have service lives of over 80 years on average. These are the time periods that we have generally used as a basis for the following analyses.

Reasoning:

- The work by [Lasvaux 2019] cited in the preceding article shows values of this order of magnitude. In this system, façade elements are generally only the outer weather protection layers of the respective system.

- The sales statistics for windows, for example, also show average usage periods of over 40 years for newly installed windows in new and existing buildings.

- The average life cycle times of a component also determine the frequency of the respective annual renewal rate for the component in question: for example, if a roof is renewed every 35 years, an average of 286 out of 10,000 roofs will due for renewal every year; this would then be a renewal rate of 2.86% - higher than the figures currently being considered for these rates (apparently the renewal rates are even below 1%/a, but this also does not seem correct to us, as incomplete surveys must be assumed. The figures determined from the sales of roofing material are more realistic. We will assume average renewal rates of between 1.5%/a and 2.5%/a and therefore the useful life of 40 years is assumed to be on the safe side.

Any intended acceleration (e.g. for progress in energy saving) or deceleration (e.g. to reduce the environmental impact of the re-use of material) must be distinguished from the actual empirical usage durations to be used for the life cycle assessments. Whether and to what extent such requirements can be realised in practice remains to be seen. For the improved components, once they have been executed with a good quality (also in ecological terms), it is mostly desirable to extend the utilisation times beyond the approaches that are usual today. On the other hand, shortening the usage duration of old oil or gas boilers, for example, may make sense in economic and ecological terms, whereby a long service life for the new systems, provided they already fulfil the sustainability goals, is just as desirable. These goals are not contradictory; however, no information can be provided on their realisation at present - for the analysis we will therefore stick to the empirical usage times currently in use.

Economic assessment

When selecting alternative options our principle was to only consider systems that remain at least affordable and preferably those that are more cost-effective in terms of life cycle costs than the “standard systems” today. We specifically point out particularly high or particularly low costs in detail. However, achieving “minimum costs” was not the focus of the Research Group Session 58.

Reasoning: Such an objective cannot be achieved also due to the inherent uncertainties, particularly with regard to cost data, as demonstrated, for example, by the gas price explosion in 2022. Estimation of the order of magnitude of the costs is possible within the scope of accuracy: this allows at least those variants to be identified that lead to very high costs regardless of future developments that cannot be predicted in detail (one example is direct electric heating: since a game-changing drop in electricity prices to less than half of today's costs cannot be expected in the foreseeable future, such systems will always have particularly high life cycle costs). There is always a risk of cost explosions when there is dependency on very high volumes of raw material supplies - as was the case with the oil crises or the natural gas crisis in 2022, for example.

On the economic side, we consider the target of “expected annuity life cycle costs not significantly higher than before 2020” to be a good goal. (For the methodology of the financial calculation, see [AkkP42]).

Life cycle: Representation on an annuity basis

The substantial measurement parameters (e.g. CO2) are effectively totalled in accordance with the “present value method” at time “0” (=present). In the field of economics, this is “discounted” at the interest rate. Such a mechanism is unknown in nature - in any case, “automatic mitigations” through future processes will be small and uncertain. The present value is therefore simply the sum over the period under consideration - minus any residual values.

For many observers, however, a total over 40 years, for example, is hard to understand because there is no clear reference. In addition, this results in values that vary depending on the author (we have seen 20, 25, 60 year observation periods, in some publications even 180 a). Of the same value is the representation considered parameter/year, which divides the total value by the length of the observation period again, known as the annuity representation.

Dispersion of data

To get an impression of the dispersion of the data on manufacturing energy and the climate impact of materials, let's look at a few examples.

Example 1: manufacture of sand lime bricks (calcium silicate CS) (process)

Fig. 1 shows the production chain for CS production. It was found that two individual processes are significant for both primary energy consumption and climate impact: firstly, burning of the primary product “lime” and secondly, curing of the sand-lime brick in an autoclave.

Fig. 2 shows 90 kWh/t primary energy energy consumption for burning the lime and 99 kWh/t for steam curing, the total rucksack according to this data is 241 kWh/t (according to [Kohler 1995]). The dominance of lime burning is even more pronounced in the CO2 data, from which come 67% of the GWP contributions totalling around 0.151 kgCO2eq /kgCS. This is a typical distribution for such processes in the raw materials industry: if thermally generated chemical material conversions are required, this leads to high primary energy demand values - in this case, the direct material release of CO2 from the CaCO3 in the lime kiln is also added. As the industry quite rightly claims, over the decades some of this released CO2 is also bound again in the course of recarbonation in the finished building. However, we have not yet included this “credit” in the calculations carried out here. This also applies (symmetrically) to the relevant process for cement in concrete.

Fig. 3 illustrates the range of published data for the primary energy demand for manufacturing (A1:A3, raw material to factory gate) of the EPDs of various CS manufacturers: these range from 0.24 kWh/kg (minimum) to 0.49 kWh/kg (maximum), i.e. they fluctuate by +60 to -21% around the value of 0.307 kWh/kgCS (according to ÖKOBAUDAT) that was subsequently used by us. This demonstrates that independent certification of production can certainly be a promising instrument for reducing climate damage. Against the background of this variance, we estimate that the reduction to around 50% of today's values which is achievable by around 2030 is feasible, with an emphasis especially on the reduction and substitution of lime, the optimisation of lime firing and the transition to the increased use of renewable energy and heat recovery in steam curing. Whether the completely climate-neutral production promised by the industry for 2045 will be possible depends above all on progress in the area of fired lime; we currently consider it premature to make a forecast on this [Geres et al 2021]).

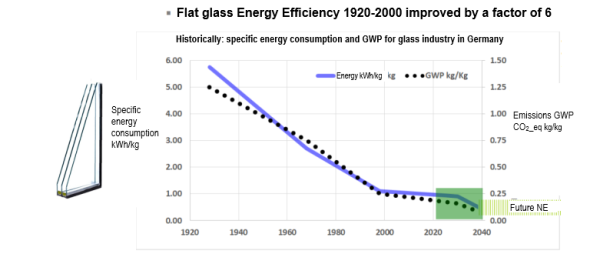

Example 2: Manufacture of plate glass

History

Fig. 4 shows the shows the historical development of primary energy consumption and greenhouse gas emissions for producing 1 kg of glass in Germany (according to [Lindig 2017]). This development illustrates the enormous increase in energy efficiency for this production: between 1930 and 2000, for example, the specific emissions were reduced from 1.25 to just 0.25 kgCO2eq /kgplate glass, which is a factor of 5 and corresponds to a reduction of 1.1% per year, which is almost linear. As recently as 1980, the widespread view was that the “physical limits” of energy efficiency had already been largely reached in the key industrial processes and that there was only a small potential of a few percentage points: between 1980 and 2000 alone, however, the specific energy requirement in glass production was reduced by a further 50%; the physical limits have by no means been reached, as we will discuss below. However, there has been a clear levelling off in the development with regard to improved efficiency since 2000.

Our hypothesis is that this is primarily due to economic conditions: between 2000 and 2020, the cost burden on the relevant sector due to energy prices (for the industry) that were no longer rising in real terms and a share of energy costs in production that has since fallen sharply was not significant; further improvement in this area was therefore no longer a priority for the industry. The call to reduce greenhouse gas emissions only came from the political and social spheres without any noticeable economic pressure and therefore had little substantial impact on management decisions based on shareholder value 4) ) . The economic conditions for this industry sector have also changed dramatically due to the 2022 gas crisis: here too, a significantly higher proportion of costs must continue to be calculated particularly for the natural gas demand; as a result, investment decisions will once again shift more strongly towards increasing efficiency and the substantial use of renewable energy. Our projection is therefore that in the coming years, the industry will again focus more on the actual realisation of the potentials of climate gas reduction in conjunction with improved efficiency as described e.g. in [Gärtner 2021]. This will lead to a noticeable decrease in emissions to around half by 2035.

Variance of data

The emissions and the primary energy demand of the data of various manufacturers of plate glass given in the EPDs differ by up to +43% and 11% respectively from the calculated value of 5 kWh/kgGlass according to ÖKOBAUDAT; we therefore estimate the relative standard deviation of the ÖKOBAUDAT data sets for the raw material glass at 25%. The influence of this uncertainty on the life cycle assessments presented in B. Krick's article is not inconsiderable in quantitative terms - but even in the most unfavourable case (25% more grey emissions), they do not result in a change in the conclusions, which are stable against this fluctuation range. However, lower emissions during product manufacturing would further reduce the grey emissions (and therefore also the overall) ecological impact.

In the analyses, we have used the values documented in [ÖKOBAUDAT] for calculations everywhere: PEr with 5 kWh/kgplate glass and GWP = 1.4 kgCO2eq /kgplate glass.

Manufacture, specifically upstream chain.

Renewable raw materials

As with all other materials, the actual expenditure for harvesting, drying, processing, transport and production (e.g. of an OSB board), including preliminary work for aggregates, can be tracked and totalled along the production tree for renewable raw materials (index: NR). Exactly this is done in the product data sheets (e.g. the EPDs).

Of course, this is also “historical data” here; we have already discussed the consequences using the example of “glass”: as a rule, the data used is higher than current data due to continued efficiency gains; we will not change this in the analyses for any of the materials listed and will therefore remain on the safe side with regard to the use of materials.

However, in the case of renewable raw materials, a further contribution is now added: C, the carbon bound in the material which must be understood as “sequestration” in the building over the period of use. It has become established practice to treat this as if the alternative were the full release as CO2 over the period under consideration 5) . This approach is correct for those raw materials that are harvested ANYWAY and have “incineration”6) as a fixed alternative use, for example straw and waste paper for which the alternative use is “co-firing” in coal-fired power plants or combustion in waste-fed heating plants or waste power plants.

The approach is certainly not correct in the case of wood for example, where the alternative compared to higher utilisation is to “leave it standing in the forest/variable retention logging” (see the following sections).

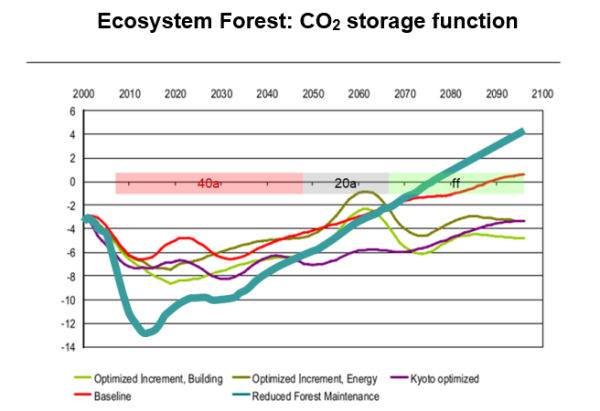

Ecosystem woodland/forest, CO 2 sequestration function

In order to be able to assess the potential of wood as a renewable raw material, the ecosystem “forest” must first be understood in terms of its sequestration capacity. During the past few decades, there have been a large number of publications on this subject; however, the debate on this is in part very controversial and, as we will see, produces quite different results quantitatively. However, the basic processes are understood in essence and are also recognised in the scientific field. The differences lie, on the one hand, in the actually different boundary conditions in climate-related and silvicultural and historical terms, as well as in the often very differently drawn spatial and temporal balance boundaries 7) .

To make it easier to understand the basic interrelationships, we present “Fig. 37 Total effects for Switzerland per year” in [Taverna 2007] as Fig. 6. We have only highlighted the curve “Reduced forest maintenance/management” (dark cyan), i.e. the least possible intervention in the forest left to itself. Based on the starting time, forest management is limited for logical reasons to the unavoidable removal of decaying wood and very old trees from the forest. A decline in the use of firewood and a decrease in the utilisation of wood can then be expected. The red curve (“baseline”) shows the current management status. The curves show the total net carbon storage sum of all reservoirs (except for the atmosphere): i.e. the additional net carbon quantities (in CO2-eq) are shown which are entered in the sum of all storage in each year - this includes, for example, the masses transferred to the storage “building” or “furniture”; in the case of combustion (which is generally assumed here at the end of use), the avoided CO2 emissions from alternative combustion of fossil fuels (energy substitution) are offset - in this case over the entire period under consideration, i.e. also in 2060 and subsequent years 8) . For use in the construction sector, the avoided emissions from the production of substituted building materials were also deducted here; this is a correct approach for balancing of the forest, but it makes the quantitative adoption of the determined data into values suitable for the evaluation of building materials more difficult - because the rucksacks of the alternative materials are precisely determined for balancing of the construction and then explicitly compared with the wood alternative 9) .

The data should be fairly reliable for a period of around 40 years from the start of the analysis (light red strip); after that, both the management strategy and the question of wood burning would have to be reassessed. What is now striking for this entire period of the first 40 years is that

- ALL scenarios lead to a (high) net sequestration of carbon. The forest therefore acts as a net carbon sink under all the strategies discussed here. This fact is pleasing and should actually make it easier to ease off debates which are often conducted with a lot of emotional vehemence.

- over the entire 40-year period, annual net total carbon sequestration is highest in the “Reduced forest maintenance” scenario. This will only change after around 40 years, although the substitution of fossil fuels continued to be offset here.

Such a result is initially surprising, as the removal of wood from the forest initially removes some of the carbon from the forest and transfers it to an “additional” long-term storage facility (the buildings). This avoids the decay that would otherwise ultimately occur in the forest. In a first approximation, this consideration is also correct, but not entirely, because a significant portion of the biomass remaining in the forest does not rot there, but remains bound in the forest floor as carbon in the long term (second-order effect). In addition, not all of the tree is removed from the ecosystem when it is felled, but parts of it remain there and initially continue to respire, i.e. (like animals and organisms/destruents) burn up oxygen and biomass to CO2, but no longer perform photosynthesis (third-order effect). The total CO2 binding capacity (photosynthetic capacity) of the forest is reduced in the first few years after a tree is felled (based on the current state) because the ground vegetation and neighbouring trees cannot immediately replace the capacity of the felled tree. The 2nd and 3rd order effects described here are directly attributable to wood utilisation and must therefore be balanced and allocated to the rucksack for wood utilisation. The following section deals with the quantitative version of these qualitatively recognised relationships.

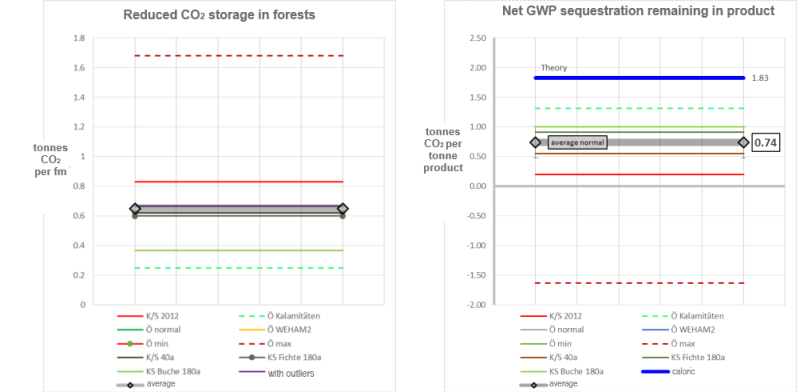

Ecosystem forest, CO 2 sequestration function, empirically

Now how great is the reduction in the CO2 storage capacity of the forest system when wood is utilised? Based on case studies under different boundary conditions, various authors arrive at a wide variation in the quantitative results, see Fig. 7. The result depends substantially on the respective circumstances; there are different scenarios for the original condition of the forest, for the selected management, different locations, tree species, etc.

The empirically determined reductions range from a minimum of only 28% up to 188% (in the latter case, even more emissions). Despite this very wide variation, however, all authors arrive at underperformance except in extreme cases.

For Fig. 8, we have used the documented data from Fig. 7 to determine the actual sequestration performance to be attributed to the product as GWP in kg per kg of wood in the product for each of the scenarios. The upper, blue limit is the calorific credit of 1.83 kgCO2eq /kgwood that is usually used (e.g. also in [ÖKOBAUDAT]). This value is not reached in any of the scenarios. We categorise the two extreme values of 1.32 (describing the exceptional case of forest damage, known as the “Disaster/Calamities scenario”) and 1.63 (describing a non-recommendable management scenario) as outliers that could have been avoided under normal circumstances. The remaining data will then lie in the range between 0.2 and 1.0 kgCO2eq /kgwood.

Literature key for the scenarios in: K/S: [Klein &Schulz 2012]; KS: [Klein et al, 2013] (the substitutions were deducted again by the authors); Ö: [Fehrenbach et al. 2022].]

For the present study we calculated with the arithmetic mean of the values of the different scenarios (without the outliers), i.e. 0.74 kgCO2eq /kgwood with a relative standard deviation of 34%. The results of most scenarios were then within the specified variance.

Practical consequences

The systematic overestimation of the GWP credits on wood is based on a methodological error as a result of ignoring the associated upstream chains. The caloric value of 1.83 kgCO2eq /kgwood that is usually applied for the product is clearly too high, regardless of which forest management model is used as a basis. Future discussions will show whether a more exact specification than the 0.74 kgCO2eq /kgwood (±34%) determined by us from the reference literature is possible.

Incidentally, the data from the respective databases for the building material wood can also be easily corrected: in each case the GWP values must be increased by the difference of the credit applied originally (e.g. 1.83 kgCO2eq /kgwood) to the realistic value of 0.74 kgCO2eq /kgwood corresponding to the wood content (dry weight) in the product. E.g. for solid structural timber (KVH):

GWP(KVH)corr = GWP(KVH)Database + (1.83 – 0.74) . mdry,wood /mProduct . r dry,wood

= - 636 kgCO2eq /m³ + 1.09 . 468 kg/m³

= -126 kgCO2eq /m³

The correction compared to the calorically determined values used in [ÖKOBAUDAT] for example, which results here is significant. This insight also has decisive impacts e.g. on the evaluation of new building strategies. The widespread idea that a massive expansion of new construction using wood would result in sequestration potentials that would more than compensate for the new CO2 emissions from these new buildings proves to be incorrect against this background. In view of the consequences of such miscalculations, it is important that the related issues are extensively discussed.

For this reason, the global warming potential (GWP in kgCO2eq) of wood products in real terms is not negative to the extent usually assumed. The sequestration performance of timber construction that is utilised is not sustainable to the differently estimated extent.

However, there is (very probably) still a certain amount of such an output and the fact remains that the GWP of timber constructions is noticeably lower than many other common constructions and is therefore associated with lower ecological impacts. This does not change the recommendation for timber constructions: there is a certain degree of sequestration, and much higher GWP rucksacks of other materials are avoided. It therefore remains the case that timber construction should be favoured wherever this is possible with reasonable effort.

Production, especially upstream chain. Renewable resources

Summary on “Sequestration in the building structure”

In the case of renewable raw materials that occur as a by-product during cultivation of crops that will already be utilised IN ANY CASE (such as cellulose or straw) and that alternatively are regularly burned or decompose on the fields within a short time, we will continue to calculate with the calorific value for a CO2 sequestration credit of 1.83 kgCO2eq /kg dry organic material kgCO2eq /kg 10) .

For wood products, a sequestration credit of 0.74 kgCO2eq /kg (dry) is used, in which the influence on CO2 storage in the forest based on current research is taken into account 11) .

Both approaches assume that subsequent utilisation does not “automatically” consist of burning of the material. Here, the general approach that any emission that does occur is applied in the event of such subsequent use has proved reliable.

Production: planning

The design of a building and specialised planning require the use of energy - especially heating energy in a conventional studio. Planners with an office in a conventional building consume approx. 4500 kWh of primary energy for a typical residential unit, or converted on an annuity basis, 0.72 kWh/(m²a) per m² of planned new build floor space. This is about 5% of the annual heating requirement of a Passive House building; thus, even this value is negligible. If the architect's office is also located in a Passive House building, the consumption is further reduced to approx. 30% or 0.225 kWh/(m²a) - which can also be completely met through renewable energy within a reasonable period of time.

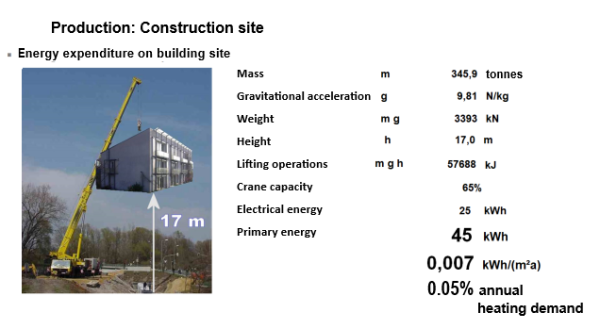

Production: construction site

Fig. 9 illustrates the orders of magnitude: even if we lift the materials of the entire building structure by 17 metres with a crane during construction and then lower it to its destination without energy recovery (which is usually not used in a crane), this will only consume a total of around 45 kWh; in annuity terms, this is 0.05% of the typical heating requirement of a Passive House.

Overall, the costs at the construction site are naturally higher, especially if there are also thermal processes such as the welding of bitumen sheets or construction heating. Tools for cutting concrete or stone can also have significant connected loads. In total, however, the energy consumption at the construction site itself is usually limited and is in the order of one to three times the annual heating demand value.

Operation: annual heating demand

The annual heating demand is the ultimately decisive parameter for operation (AHD; stated in kWh/a or specific kWh/(m²a) in relation to the heated floor space). This is the interface between the building and the building technology and the appropriate parameter for characterising the quality of the building.

We relate the AHD to the heated floor area (treated floor area TFA). This is a clearly defined international parameter that characterises the benefit/usefulness of the implemented building. It should be noted that many national legal specifications have introduced other reference values (e.g. Germany with the 'useful floor area AN' according to EnEV or GEG, Austria according to Önorm and Switzerland according to [SIA 380:2015]). None of these national specifications are comparable with each other (nor can they be meaningfully converted, as different methodologies are used in each case), and they are all considerably larger (10% to over 30%, depending on the property) than the TFA we use. As a result, the national specifications make the specific heating requirement values appear systematically lower than those calculated using the TFA. This effect is entirely intentional on the part of the respective governments, because it puts the efforts for saving energy in a better light. However, since the consumption surveys again are regularly based on living space or rented floor space in the usual billing methods - as usable space, this is often smaller than the reference areas established in national law and is of the same magnitude as the TFA - the empirically collected actual consumption values appear higher than the demand values calculated according to national specifications for this reason alone; this already explains a substantial part of the so-called “performance gap”. This discrepancy is avoided if, as we have systematically done here, the same reference value, namely the TFA, is used in general.

To determine the future energy consumption values and emissions for the heating task, calculation methods for the heating demand must be used as soon as the building is newly constructed or its structural substance is changed (e.g. modernised). In terms of methodology, the calculation according to the Passive House Planning Package [PHPP] has proved effective especially for modernised old buildings. [Schnieders 2018] provides a method for properly taking into account the repercussions of heating carried out only partially and temporarily, especially in old buildings.

Reasoning: The PHPP method has been validated over many years using measured consumption values, see [Johnston 2020]. For the heating demand of old buildings, when used properly it also produces results which correspond well with long-term averages of the measured consumption values.

As already described in the first section, we will use the following benchmarks to assess the sustainability of the respective solutions:

- The required primary energy, based on PEr, 'Primary Energy Renewable'

Reasoning: - this is a benchmark that is independent of time and specific boundary conditions - PEr is a measure of the actual effort (e.g. required floor area/footprint) for sustainable energy production - PEr therefore determines the achievability and costs of the energy transition and there is no alternative to the switch to renewable energy in any case.

- CO2eq emissions cumulated over the life cycle

and presented on an annuity basis (i.e. average value of annual CO2eq emissions over the entire period under consideration) Explanation for e.g. the use of gas heating systems: partial substitution by biogas and hydrogen is included, assuming climate-neutral gas in 2070 (linear decrease in GWP until then). On average, the result for gas heating systems (2022-2062) is: natural gas: GWPgas = 149 gCO2eq /kWhFinal (current value: 250).

The following results for the electricity consumption of a heat pump for heating: Heat pump electricity: GWPel,HP = 198 gCO2eq /kWhFinal (today's value: around 500 to 600)

The value used for heat pump electricity is derived in the next section.

Operation: Heat pumps as the baseline scenario

The issue of climate-friendly heating systems will only be systematically addressed in AK60. However, we anticipate one outcome here. Two systems prove to be sustainable if the supply side of the grid-bound energy sources used for this purpose is operated responsibly:

- the use of district or local heating

- heat pumps

Both can achieve significantly lower PEr and GWP values than any alternative form of active heating, especially gas-fuelled heating systems.

A major part of the future heating demand after the switchover will be met by electrically powered heat pumps, because although the expansion of heat supply networks can be expanded considerably, it cannot be achieved on a broad scale. The assessment of performance and emissions of district and local heating systems will be dealt with in detail in AK60. Generally, the results of the life cycle analysis do not deviate significantly from the “heat pumps” alternative.12)

Electrical energy is drawn from the electricity grid to operate the heat pumps, especially in winter (this must be taken into account in the analysis because electricity generation in summer can be switched to CO2 free sources more easily and quickly).

The German government's announcement envisages 6 million heat pumps by 2030. This corresponds to a conversion rate of 1.5% per year (for existing fuel-operated heating systems) and would take around 60 years for a complete switchover. It is clear that this would be too slow to achieve the climate targets.

We will therefore take a more optimistic view and assume a conversion rate of 3% p.a. and a corresponding timeframe of 33 years (i.e. by 2055) until a complete switchover. Incidentally, this would mean that more than half of the boilers that are due to be replaced in the future would be replaced by heat pumps - this is a very optimistic but entirely feasible scenario. The vast majority of the heat pumps installed would then go into existing buildings. In the baseline scenario, these are average existing buildings with heating loads of over 60 W/m². Even if panel heating systems are installed in properties with such high heating loads, annual performance factors (Heating Seasonal Performance Factor: HSPF) of over 3 on average cannot be expected in this way. Below, we will optimistically assume an average HSPF = 3 for the heat pumps used, unless explicitly indicated otherwise.13) The share of renewable energy (RE) used to generate electricity is decisive for the global warming index of electricity. For the baseline scenario, we will assume consistent implementation of the German government's targets, according to which annual expansion will be as follows:

- wind energy “onshore” increase by +11.5 TWh/a (4.8)

- wind energy “offshore” increase by + 4 TWh/a (3.8)

- photovoltaic installations increase by + 7 TWh/a (3.8)

The values in brackets are the empirically determined average increases in the relevant electricity generation in the period from 2000 to 2020 (offshore 2013-2020 [AgEB 2021]). We will discuss the influence of different RE expansion scenarios in the following section.

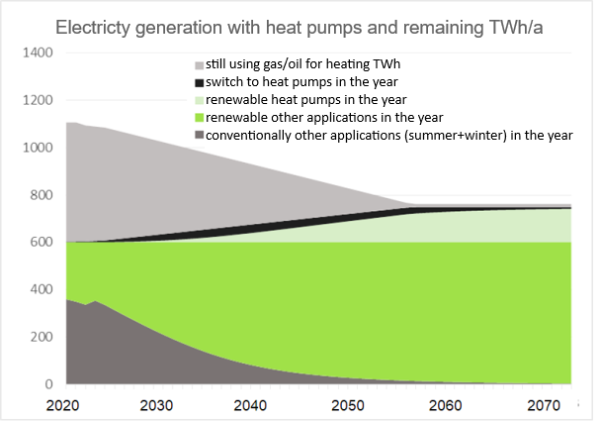

With these parameters, the scenario shown in Fig. 10 results for the final energy of electricity and the remaining fossil oil and gas demand for space heating (all sectors, light grey). The scenario shows:

- The phasing out of fuel use for heating, which occurs almost linearly from 2023 to almost zero in 2057 (some of these fuels will increasingly be provided through renewable sources, see last section).

- The rapid changeover of electricity generation to renewable energy (shown in green). Continuing linearly from 2023, this would be achieved by around 2038 with the conversion rates used; however, it must be taken into account here that with increasing coverage percentages of renewables, the non-simultaneity of generation and demand increases considerably, resulting in a constantly increasing demand for energy storage. Conversion into storable forms of energy and reconversion into electricity require additional energy, which results in a decrease in the conversion rate over time for the conventional electricity generation shown in grey.

- An increasing proportion of the additionally generated electricity (especially wind power) can be used for additional electricity applications (light green: electricity generated from renewable sources to supply heat pumps; we have covered the additional electricity demand for electric traction in transport and the switch to electricity-powered systems in industry here by assuming that the total electricity demand (except for heat pumps) remains constant; this is a method also widely used by other authors. It was assumed that previous electricity demand values will decrease due to improved efficiency to the same extent as the increase in such additional electricity demand values. For the years 2006 to 2020, this approach proved to be well validated based on the energy data from the [BMWi]).

- Switching space heating from oil and gas (previously around 500 TWh/a) to heat pumps means a considerable additional demand for electricity, especially for the winter. This electricity demand can no longer be covered by savings in other areas of application, instead it requires additional power plant capacity. The associated electricity generation is shown in the diagram in dark grey (for conventionally generated electricity) and light green (for electricity generated from renewable sources, in this case primarily wind power); after 2053, this amounts to around 150 TWh/a when the switchover is complete.

- In the initial period (up to approx. 2032), the additional electricity required by heat pumps will have to be generated on an additive basis. Additional power plants will have to be operated for this purpose (especially in winter) – initially this won't be renewable electricity generation at first, as this can continue to be used for already existing applications von bereits bestehenden Verbrauchern abgenommen. For this reason, the electricity generators initially allocated to heat pump electricity are, at best, predominantly natural gas-fired combined cycle power plants. This is shown in the diagram by the initial increase in electricity generated from fossil fuels (dark grey) for the heat pumps. The emission factor for natural gas-fired combined cycle power plants is decisive for the greenhouse gas balance; this is GWPCCGT = 455 gCO2eq /kWhFinal .14)

- The renewable share of total electricity generation progresses over time and as already explained above, more and more renewable electricity remains for the operation of heat pumps (light green). However, the switchover will take place over a long time, as electricity will still have to be generated in fossil-fuelled peak-load power plants during the periods of low production until renewable energy storage technology is fully developed. In poorly insulated buildings in particular, the maximum heating load also coincides with the gaps in electricity generation through wind power in winter (cold high-pressure weather conditions with little wind).

Fig. 11 shows the development over time of the factors for greenhouse gas emissions from electricity generation in this scenario. The emission factors for average electricity consumption without any particular seasonal dependency, such as for the operation of industrial plants, household appliances or transport are shown in orange. These emissions are quickly reduced by the expansion of renewable generation capacity: there are no significant peak loads and the mix of wind and solar energy is also able to ensure reasonably balanced supply over the whole year. Fluctuations during the day can be compensated for comparatively easily using storage technologies that are already available today. The emission factors for heat pump electricity that are used for space heating are shown in grey. Their electricity demand is concentrated almost exclusively on November-March, meaning that almost exclusively wind energy is available here for direct coverage from renewable energy. Gaps in wind power generation must therefore still be compensated for through peak-load power plants, even with a high level of expansion, and these will still be operated using fossil fuels for longer periods of time. For these reasons, the emission factors for heat pump electricity are higher than those for average electricity consumption, both today and over the entire period under consideration.

The integral of the emission values results in average emission values for the next 40 years for

average electricity use GWPel,ø = 93 gCO2eq /kWhel,ø

heat pump electricity use of GWPel,HP = 198 gCO2eq /kWhel,HP

The value for heat pump electricity documented here was used for the calculations in AK58. This is considerably cheaper than in the current situation and also cheaper than electricity generated using natural gas in combined heat and power plants. However, under no circumstances is there zero emission of greenhouse gases for heat pumps powered by electricity within the period under consideration.

Operation: Electricity for heat pumps

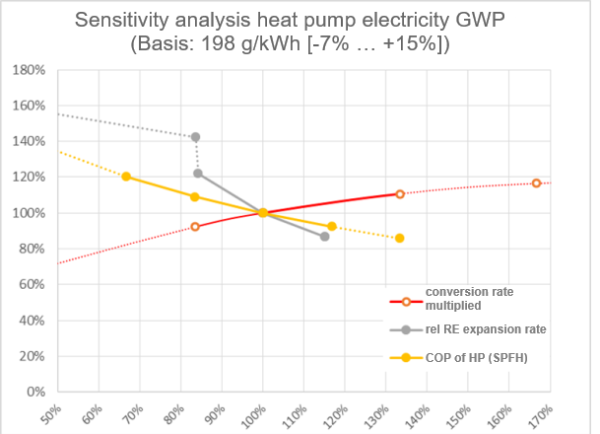

Sensitivity tests / scenarios The future value for the greenhouse gas emission factor of the electricity GWPel depends on a number of currently uncertain assumptions regarding the boundary conditions. We will vary the most important of these in this chapter and thus test the sensitivity of the emission factor.

Fig. 12 shows the results of this sensitivity analysis; the relative values of the emission factor (in % compared to 100% = baseline scenario) are plotted on the Y-axis, and the relative changes in the particularly sensitive parameters are plotted on the abscissa. These are

• The rate of conversion to heat pumps is shown in red in the diagram; the basic assumption for this is 3%/a. If the changeover is less quick (only 2.5%/a), then less additional electricity will be required and this can be decarbonised more quickly using the additionally installed wind power; GWPel will then decrease by 8%. On the other hand, this extends the time until the complete switchover to renewable energy to such an extent that it will hardly be possible to meet the climate targets. Overall, the influence of this parameter on the outcome will only be small due to the opposing overall influences.

• The expansion rate of renewable energy, shown in grey in the diagram. With strongly accelerated expansion (+26 TWh/a), the GWPel will be reduced by 13%. With only moderate expansion (but still higher than 2015-2020), the GWPel will increase by 22%. If, as is currently being discussed, coal-fired power plants are put back into operation for a few years to substitute highly expensive natural gas for electricity generation, emissions will increase by 42%. As expected, this parameter is sensitive, though there is a great risk of higher emissions in the end due to geopolitical and global economic conditions. This makes the consistent expansion of renewable electricity generation and the reduction of the heating demand through energy retrofits of existing buildings all the more important.

• The overall seasonal coefficient of performance of the heat pump system is shown in yellow in the diagram. The baseline value here is HSPF 15) = 3; if the heat pumps used are better, less additional electricity will be consumed - this is almost exclusively due to the fossil-based peak load generation, so that an 8% reduction in the emission factor results with an average HSPF of 3.5 here; at the same time, consumption is also approximately 14% lower, of course - the total reduction in emissions thus amounts to 21%. Conversely, poorer coefficients of performance lead to higher emissions (up to +20%). High coefficients of performance for heat pumps are therefore an important instrument for the success of the energy transition. In particular, independently tested, practice-oriented values must be available for labelling of the appliances. We will address the related issues in more detail in AK60.16)

On the basis of the alternative scenarios we have analysed here, we estimate the range of variation of the greenhouse gas emission factor for heat pump electricity as GWPel = 198(-14 … +30) gCO2eq /kWhel,HP

Sources

[AGEB 2022] Bruttostromerzeugung in Deutschland von 1990 bis 2021 nach Energieträgern (Gross electricity generation in Germany from 1990 to 2021 according to energy sources). (PDF) Arbeitsgemeinschaft Energiebilanzen e. V., accessed on14. June 2022.

[Agora 2022] Agora Energiewende: Agorameter, Stromerzeugung in Deutschland (Electricity generation in Germany), https://www.agora-energiewende.de/service/agorameter/chart/power_generation

[AkkP 42] Feist, Ebel, Kah, Huse, Baumgärtner, Pfluger, Kaufmann: Ökonomische Bewertung von Energieeffizienzmaßnahmen (Economic evaluation of energy efficiency measures), Research Group for Cost-effective Passive Houses Protocol Volume No. 42. Passive House Institute, Darmstadt 2013

[AKKP 56] Feist, Wolfgang (Hrsg.): Energieeffizienz und erneuerbare Energien: Zielkonflikt oder Synergie? (Energy efficiency and renewable energy: Conflict of objectives or synergy?), Research Group for Cost-effective Passive Houses Protocol Volume No. 56. Passive House Institute, Darmstadt 2021

[BMWi 2020] German Federal Ministry of Economics, Figures and Facts: Energy Data, available at http://www.bmwi.de/Navigation/DE/Themen/energiedaten.html (July 2022)

[EN 15978] DIN EN 15978:2012-10: Nachhaltigkeit von Bauwerken – Bewertung der umweltbezogenen Qualitäten von Gebäuden – Berechnungsmethode (Sustainability of construction works - Assessment of environmental performance of buildings - Calculation method); German version EN 15978:2011

[Fehrenbach et al. 2022] Fehrenbach, M. Bischoff, H.Böttcher, J. Reise, K.J. Hennenberg: The Missing Limb: Including Impacts of Biomass Extraction on Forest Carbon Stocks in Greenhouse Gas Balances of Wood Use in Forests, 2022 https://www.mdpi.com/1999-4907/13/3/365

[Feist 2014] Feist, Wolfgang: Passivhaus das nächste Jahrzehnt (Passive House - the next decade). In Conference Proceedings of the 18th International Passive House Conference 2014 in Aachen. Passive House Institute, Darmstadt, 2014

[Gärtner 2021] Gärtner, S. et al: Simulation and Techno-Economic Analysis of a Power-to-Hydrogen Process for Oxyfuel Glass Melting. Energies 2021, 14, 8603.

[Geres et al 2021] Geres, R. et al: Roadmap für eine treibhausgasneutrale Kalksandsteinindustrie in Deutschland (Roadmap for a greenhouse gas neutral sand-lime brick industry); published by KS-Industrie, 2021; available online: https://www.kalksandstein.de/media/08_downloadcenter/01_roadmap_kalksandsteinindustrie_langfassung.pdf

[AKKP 56], [Grove-Smith et. al. 2021] Grove-Smith, Feist, Schnieders, Krick: Primärenergiebewertung in einer Erneuerbaren Energiestruktur (Primary energy evaluation in a renewable energy supply: the PER system). In Research Group for Cost-effective Passive Houses Protocol Volume No. 56, pages 65-106

[Hennenberg et al. 2019] Hennenberg, K., H. Böttcher, K. Wiegmann, J. Reise, H. Fehrenbach: Kohlenstoffspeicherung in Wald und Holzprodukten (Carbon storage in woodland and wood products); in: AFZ Der Wald, 2019

[Johnston 2020] David Johnston, Mark Siddall, Oliver Ottinger, Soeren Peper und Wolfgang Feist: Are the energy savings of the passive house standard reliable? A review of the as-built thermal and space heating performance of passive house dwellings from 1990 to 2018; Energy Efficiency (2020) 13:1605–1631

[Klein; Schulz, 2012] Klein, D., C. Schulz (2012): Die Kohlenstoffbilanz der Bayerischen Forst und Holzwirtschaft (Carbon balance of the Bavarian Forest and the timber industry); Bayerische Landesanstalt für Wald und Forstwirtschaft (LWF) Abschlussbericht 09/2012

[Klein et al, 2013] Klein, D., S. Höllerl, M. Blaschke, C. Schulz et al: The Contribution of Managed and Unmanaged Forests to Climate Change Mitigation — A Model Approach at Stand Level for the Main Tree Species in Bavaria; in: Forests 2013, 4, 43-69; doi:10.3390/f4010043

[Kohler 1995] Kohler, N.: Baustoffdaten, Ökoinventare (Building materials data, life cycle inventories); ifib Karlsruhe; HAB Weimar; ESU-ETH Zürich; 1995

[Lasvaux 2019] Lasvaux, S. et al. DUREE Project Analysis of lifetimes of building elements in the literature and in renovation practices and sensitivity analyses on building LCA & LCC. Final report for Swiss Federal Office for Energy (SFOE), 2019

[Leturcq, 2020] Leturcq, Philipp: GHG displacement factors of harvested wood products: the myth of substitution: in: Nature, 2020

[Lindig 2017] Lindig, M.: Glass melting technology addressing the environmental trend. Proceedings of the 91st Glass Technology Meeting of DGG, Weimar, 2017.

[ÖKOBAUDAT] https://www.oekobaudat.de/ (Sustainable Construction Information Portal)

[Passipedia 2016 - 2023] Passipedia, The PER sustainability assessment, online-publication, Passive House Institute, 2016; https://passipedia.org/certification/passive_house_categories/per, and https://passipedia.org/basics/energy_and_ecology/primary_energy_renewable_per?s[]=per

[Schnieders 2018] Schnieders, Jürgen: Warum im Altbau nicht so viel geheizt wird wie gedacht – ein Erklärungsversuch (An attempt to explain why old buildings do not consume as much heat as was thought). In: Conference Proceedings of the 22nd International Passive House Conference, Munich 2018, Passive House Institute, Darmstadt 2018

[SIA 380:2015] Swiss society of Engineers and Architects: SIA 380; Grundlagen für energetische Berechnungen von Gebäuden (Basis for energy calculation of buildings), Zurich, 2015

[Soimakallio et al. 2022] Soimakallio, S., H: Böttcher, J. Niemi, F. Mosley, S.Turunen, K. J. Hennenberg, J. Reise, H. Fehrenbach: Closing an open balance: The impact of increased tree harvest on forest carbon. in GCB Bioenergy, 2022 https://onlinelibrary.wiley.com/doi/epdf/10.1111/gcbb.12981

[Taverna, Hofer et al., 2007] Taverna R., Hofer P., Werner F., Kaufmann E., Thürig E.: The CO2 Effects of the Swiss Forestry and Timber Industry. Scenarios of future potential for climate-change mitigation. Environmental studies no. 0739 (2007); Federal Office for the Environment, Bern. 102 pp.

[Werner et al. 2009] Werner, F. R. Taverna b, P. Hofer, E. Thürig, E. Kaufmann (2009): National and global greenhouse gas dynamics of different forest management and wood use scenarios: a model-based assessment; in: Environmental Science & Policy, 2009

See also

Life Cycle energy balances, Embodied energy and the Passive House Standard

Energy efficiency and greenhouse gas emissions over the life cycle