Table of Contents

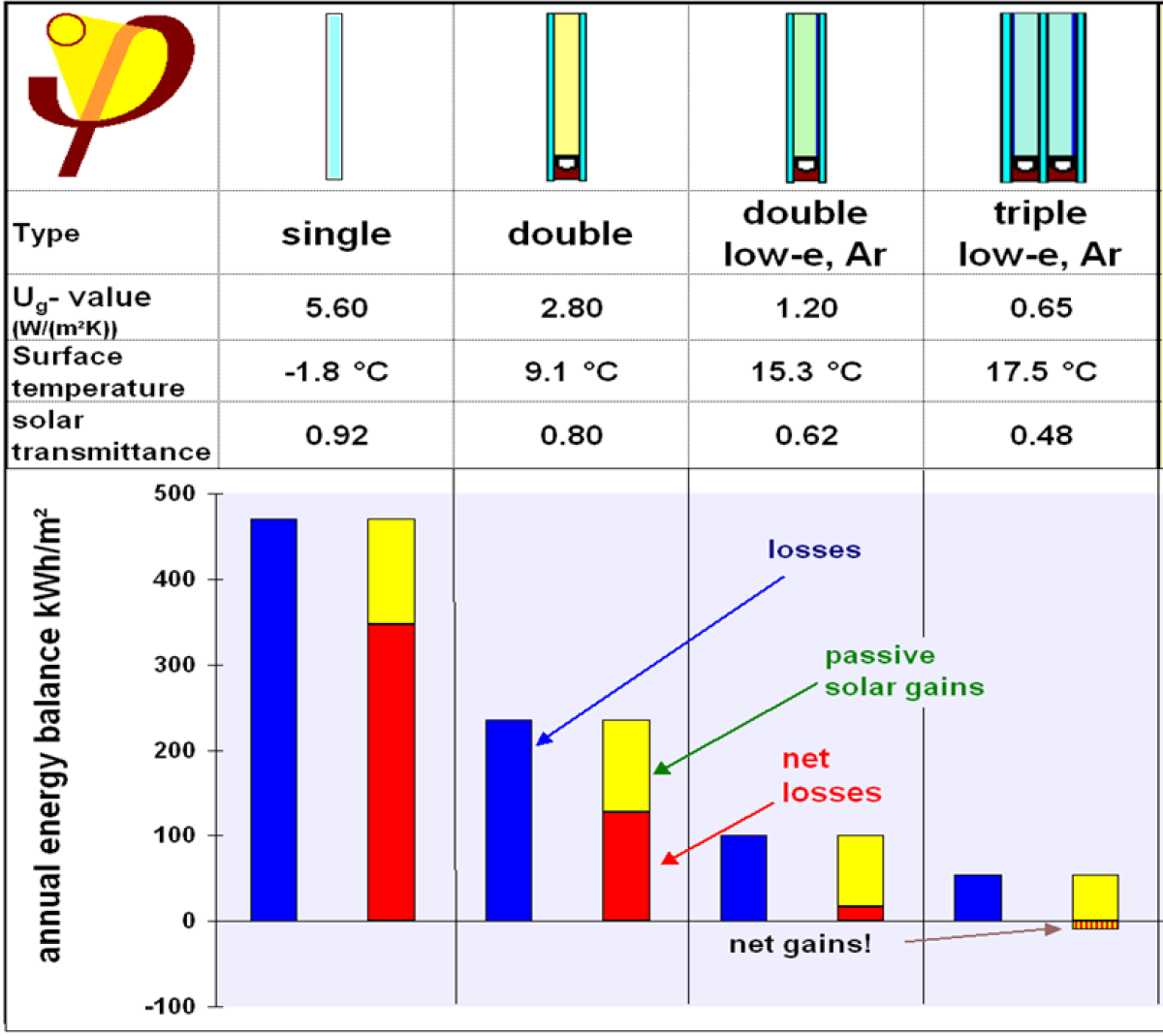

Types of glazing and their specific values

Development of windows

Quality thermal protection for windows has advanced more rapidly than for any other building component. The overall heat transfer coefficient (Uw-value) of windows available on the market has been reduced by a factor of 8 in the last 40 years!

Single glazing - it's about time this was replaced

At the beginning of the 1970s, most windows in Germany had single glazing:

- the U-value was about 5.5 W/(m²K),

- the annual heat losses through 1 m² of such a window were equivalent to the energy expenditure from 60 litres of heating oil

⇒ Assuming average energy prices in Germany, each square metre of such a window “costs” € 42 in heating energy each year.

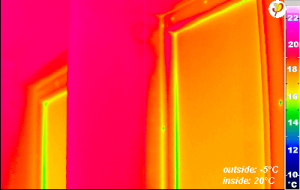

Not only the energy losses are increased, however. Due to the poor insulaton, the cold can directly reach the interior surfaces. The temperature there is often below 0°C, and is visible as frosting (see the frost patterns in the picture). Poor thermal protection is associated with decreased comfort and increased risk of damage .

"Insulating" glass: intermediate stage in need of improvement

The so-called insulating glass panes were somewhat better. They were installed in new and  modernised buildings after the first oil crisis. There is a layer of insulating air between the two panes.

modernised buildings after the first oil crisis. There is a layer of insulating air between the two panes.

- The thermal transmittance coefficient is reduced by the air layer to about 2.8 W/(m²K), which means that the heat losses are about half of those of the single glazing.

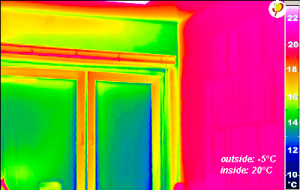

- The interior surface temperatures of double glazing on very cold days are about 7.5 °C. There are no frost patterns any more, but the window surface is still unpleasantly cold. In cold weather, there will be condensation, because it falls short of the dew point (see picture right hand side).

- The heat losses cost about € 21 per m² each year - and that adds up in 15 years to more than the initial cost of the window itself. Many windows in existing buildings still have these so called “insulating glass panes”.

Double low-e glazing: much better, but still not good enough

Significant progress is possible by a scientific development made by Prof. Glaser in Germany and Prof. Rosenfeld in California: by applying an extremely thin metallic coating (low-e coating) to one of the glass surfaces in the space between the panes, the heat radiation between these panes can be greatly reduced; and most of the heat is transferred by heat radiation (longwave infrared).

- Furthermore, the space can be filled with inert gases, usually Argon, which has a lower heat conductivity than ordinary air. Thus this so called “heat protection glazing” or “low-e-glasing” became the standard product with the German building regulation of 1995 and was since then used everywhere for new constructions and modernisations.

- An interesting fact is that “glazing” has not become more expensive in spite of the enormously improved quality.

- An ordinary window with wood or plastic frames and ordinary spacers with the currently used heat low-e-glazing has U-values between 1.1 und 1.7 W/(m²K). This means that the heat losses are only half of those of the old insulated glazings without low-e coating.

- The average interior surface temperature is now some 13°C in minimum even at frosty outdoor temperatures (-15°C). However, there is still cold air descent ocurring at the window and uncomfortable temperature stratification may still occur in the room. In Central Europe condensation only occurs on the inside on the edges with this quality of glazing .

Triple glazing with two low-e layers: optimum quality for new construction and for modernisation

The breakthrough for energy efficient construction in Germany was triple glazing using two low-e-layers.

- It consists of two spaces between panes with one low-e coating each and inert gas filling, resulting in U-values between 0.5 and 0.8 W/(m²K).

- In order to achieve this level of quality for the whole window and not just for the glazing a well-insulated window frame and a thermally separated spacer should also be used in addition.

⇒ The result is a “comfort window”, also called “Passive House window” which reduces the annual heat losses to less than the equivalent of 7 litres of heating oil per square metre – less than one eighth of the initial amount.

If one also takes into account that the (cost-free) passive solar energy entering through the Passive House window almost compensates for the heat losses in winter, the net losses through windows of this quality are negligible; in a lot of climates it will be a net-energy-gain window. Besides that, the additional investment for the better quality is compensated for by the energy savings due to the low-e triple glazing alone.

The windows' potential for solar gains just matches the thermal protection level of the insulated envelope (with U-values of about 0.15 W/(m²K)). It is only by combining these two qualities that Passive Houses can be realised in cold climates such as typical for Central Europe - or in even colder ones, even those near to the polar circle. The result is a house with negligible heat losses, which stays comfortably warm and can be heated with a very low energy demand.

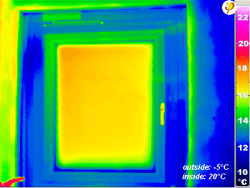

The Passive House window excels in that it not only has lower heat losses, but also provides improved comfort. Even with cold outdoor temperatures like -15°C, the interior surface temperature does not fall below 17°C.

- Thus, there is no perceptible “cold radiation” from the window.

- Besides, there is no uncomfortable air temperature stratification in the room, even if there is no radiator underneath the window. Of course, this result can only be achieved with all other Passive House criteria being fufilled at the same, e.g. airtightness and minimised thermal bridging.

In these circumstances the thermal comfort in the room is ensured independently of the type of heating supply. That this was made possible, is due in considerable part to the the improved windows.

Here are the important components of a window suitable for Passive Houses in cold moderate climates :

- Triple glazing with two low-e coatings,

- Insulating window frames,

- Insulating mullion-transom constructions,

- Thermally separated spacers,

- Tools for the thermal-bridge-free assembly and airtight installation of windows.

Conclusion

Passive House windows are high quality products which are now produced and supplied by more than 200 manufacturers. The energy savings achieved by these windows do not amount to just a few percent, in fact they amount to more than half of the heat lost through windows. They not only save energy but also money, and also contribute to climate protection. Passive House windows are a good example of efficient technology which has been developed in Europe and which creates jobs in the region, and at the same time relieves the burden on the energy market - especially dependencies on monopolistic energy suppliers.