Table of Contents

Insulating window frames

The fact that window frames of existing buildings are the building components with the poorest level of thermal protection is surprising for many. This is especially true if these are old window frames consisting of plastic or even metal. There are two completely different ways to improve this:

- Replacing the old windows with a new Passive House window 1); this is always best done if a window already needs to be replaced anyway; in which case attention should mainly be given to a good quality of the new window because it must again last for a long time and should have low heat losses, which will save heating costs, improve thermal comfort and save greenhouse gases. Here, a good quality means triple low-e glazing and a well-insulated window frame with a narrow facing width.

- Manually improving the old window – which can also be done on a do-it-yourself basis, as we will describe below. This will “be worthwhile” only if the old window 'lasts' another few years (10 years). 2)

By the way: insulated window frames have been tested for more than 30 years in the Passive House building in Darmstadt Kranichstein, where we used this method with a conventional frame due to there being no windows of a good thermal quality available at the time. This worked well and a comprehensive follow-up inspection was carried out after 25 years [Feist 2020]. The experiences with this were so good that more and more window manufacturers decided to develop optimised frames 3), a great variety of which are now commercially available. Of course, for new constructions or window replacement it is much easier today to use such a Passive House window with improved insulation integrated into the frame.

How to do it:

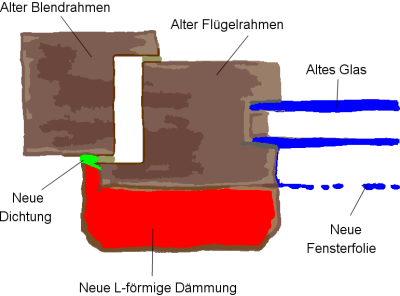

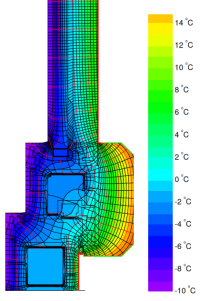

| The principle: the old frame often has a thermal transmittance of 2 W/(m²K) or more. A lot of heat passes through and the surface also becomes very cold, which is even worse if heating energy is lacking. We can change that: solid insulation panels have thermal conductivities which are around a quarter to less than a tenth of the old material of the frame. Just 2 to 4 cm of this will reduce the heat flow considerably and improve thermal comfort. The material must fit tightly, indoor air should not be able to flow behind it 4). Airtightness of the window can also be improved at the same time. With some manual dexterity, we managed to achieve this (picture series). |  |

| Two sample pieces cut from EPS insulation material using a hot-wire cutter. With a lip seal for better sealing of the window casement, and prepared for sticking onto the frame. The inside can be designed according to the new “outfit”. In our case we made it trendy… |  |

As a first step, the measurements of the window casement were transferred to the insulation panel. These can be cut into shape using a hot-wire cutter. The connections between the sections were “mitre cut” 5) . |  |

| The interior side can be designed using duct tape – which also protects the material. Obviously it's not meant to last hundreds of years – such an old window will also be replaced at some point, but this measure can help keep heating costs down for a couple of years. As the saying goes, temporary measures often last the longest . |  |

| Details about taping, cutting notches for the casement handle and ensuring airtightness are provided in the DIY instructions. This is what it looks like with only two pieces missing, with the right side completed – and if you want, you can decorate the tapes with self-designed motifs. |   |

| We also carried out the calculations: the losses from an old frame can definitely be reduced by around a third, and this without taking into account the improved level of airtightness. |  |

Back to overview of "Structural Measures"

Reference Literature

| [Feist 2020] | Wolfgang Feist; Rainer Pfluger; Wolfgang Hasper: “Durability of building fabric components and ventilation systems in Passive Houses” Energy Efficiency 13(3) Dec. 2020 DOI: 10.1007/s12053-019-09781-3; (direct link to full-text publication: Durability Passive House) |